I intend to install Deutsch connectors on my stator wires and would like to hear opinions on:

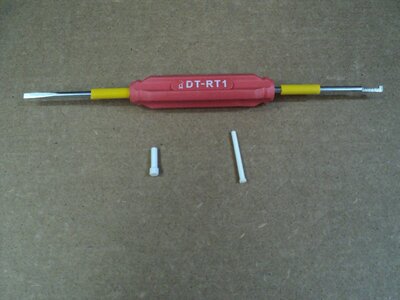

1.What model/series is everyone using (DT, DTM, Black, Grey)?

2.Are you using Deutsch or the Deutsch "type" compatible? Any noticeable differences?

3.Solid or stamped pins, gold or nickel?

4. What size(gauge)? 22,18,16,14?

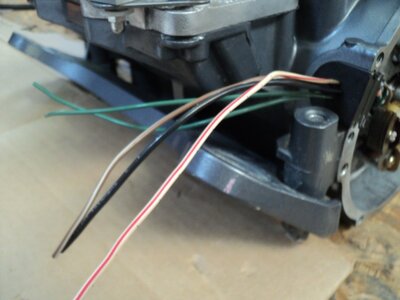

5.Where you locating? Box end ,flywheel end, in the middle?

6.Any horror stories/regrets?

1.What model/series is everyone using (DT, DTM, Black, Grey)?

2.Are you using Deutsch or the Deutsch "type" compatible? Any noticeable differences?

3.Solid or stamped pins, gold or nickel?

4. What size(gauge)? 22,18,16,14?

5.Where you locating? Box end ,flywheel end, in the middle?

6.Any horror stories/regrets?