- Location

- Cumming, Georgia

To start this off, I got my first stand up this past summer, a mint 88' 650SX I found a deal on. Having ridden dirtbikes and sit downs most my life, I was soon looking for a faster and more nimble ski. I stumbled upon this 1996 Superjet which looked pretty decent and seemed to have a lot of aftermarket parts on it. After seeing it in person, it had most all the listed upgrades but was in much worse shape than the pictures, and I now know it's worse than I originally thought lol.

It's really a 1996 but whatever, it already has a decent list of aftermarket parts, there's a handful more on the ski too.

Doesn't look too bad, I'd say it's in decent shape.

This is how it really looked when I got it. Cracked tray, cracked nose under the bumper, a good amount of spiderweb cracks, 2 cracks in the hull and a whole lot else. I got the guy down on the price a good bit and it ripped hard when I test rode it. After Georgia weather went from high seventies to mid fifties in the span of a couple weeks, I decided it was time to do some work on it.

Got everything stripped down in a few hours and learned what I needed to do. The carbon job I would rate 5/10. It's delaminated in a few spots on the sides and it doesn't look like they used enough resin to wet it out good. However it is stuck good enough for the most part and I think it would be more work, hassle and cost to take it out and redo it than it's worth. It seems like someone spent some decent money in parts on this thing but didn't really care to install it properly or take care of it at all. Evidently, one of the pump mounting nuts got stripped so rather than tap it larger, or helicoil it, or replace the nut, or just run with 3 bolts, they decided to drill through the tray and put a nut on top. Obviously, once they tightened it crushed and cracked the tray, also soaking the foam.

A close up of the hackery. Also the footholds were installed with just thickened (hopefully epoxy) and no glass. Needless to say, one of them is cracked pretty good.

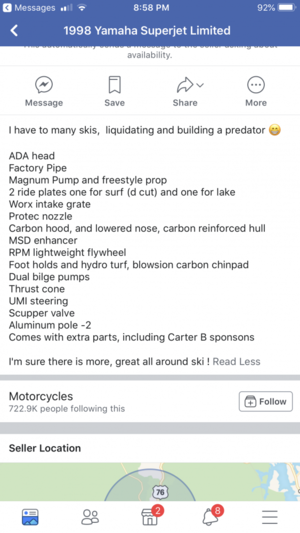

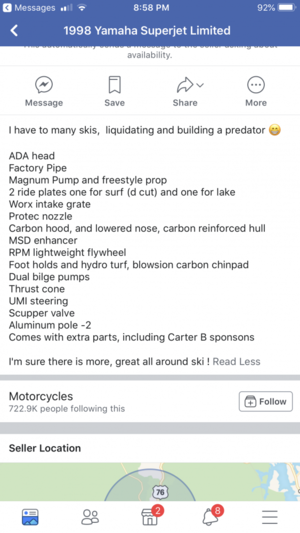

It's really a 1996 but whatever, it already has a decent list of aftermarket parts, there's a handful more on the ski too.

Doesn't look too bad, I'd say it's in decent shape.

This is how it really looked when I got it. Cracked tray, cracked nose under the bumper, a good amount of spiderweb cracks, 2 cracks in the hull and a whole lot else. I got the guy down on the price a good bit and it ripped hard when I test rode it. After Georgia weather went from high seventies to mid fifties in the span of a couple weeks, I decided it was time to do some work on it.

Got everything stripped down in a few hours and learned what I needed to do. The carbon job I would rate 5/10. It's delaminated in a few spots on the sides and it doesn't look like they used enough resin to wet it out good. However it is stuck good enough for the most part and I think it would be more work, hassle and cost to take it out and redo it than it's worth. It seems like someone spent some decent money in parts on this thing but didn't really care to install it properly or take care of it at all. Evidently, one of the pump mounting nuts got stripped so rather than tap it larger, or helicoil it, or replace the nut, or just run with 3 bolts, they decided to drill through the tray and put a nut on top. Obviously, once they tightened it crushed and cracked the tray, also soaking the foam.

A close up of the hackery. Also the footholds were installed with just thickened (hopefully epoxy) and no glass. Needless to say, one of them is cracked pretty good.