Driveline Conversion and Lower Deck Finish Part 1 (Twisted Certs and A pain in the Rhaas)

Driveline Swap Kit

This post is going to seem fairly critical of the parts I have, please understand that I am not badmouthing the company nor the parts themselves. I fully understand that making a full driveline swap that fits a fiberglass hull made in 1987 using components from 3+ other skis is not a trivial task. I also understand that there is quite a bit that goes into fabricating a component inexpensively while still making it suitable for our application. The components are well thought out and fill a niche that is highly specialized and I am happy that someone took the time to put it together. I have used the Rhaas motor mounts and adapter plates on this project and have been very happy with their components.

On the driveline conversion pieces, I opted to save some money and purchased the cheaper composite plate rather than the upgraded aluminum one. I feel like I made a mistake in doing so and will be reaching out to see if I can purchase the plate separately. This post is in no way asking for a handout nor do I expect one. The components are some form of molded polymer with fiber reinforcement. I am not a plastics/composite guy so I don't know specifics. I will say that the pictures on the Rhaas Products website made it look like the plate was fiberglass while the actual part is more close to a plastic reinforced with some kind of mesh. Again, not an expert.

Given that its not a race ski and it is probably better to flex the plate than crack it, this is not the end of the world.

Since I removed the rear hull extensions, I will probably end up cutting the plate shorter since it hangs off a fair bit now.

The shoe adapter required some massaging to seat properly. To clear the steering cable passthrough, I had to cut away enough material that I broke through into the seal area. I am not sure if this will end up being an issue since the directions suggest a healthy coating of 5200 over everything.

The machined components look well made and come anodized. The surface finish is a little coarse but its an adapter plate so who cares. I was a little surprised how much work went into developing the swap kit, none of the parts are at a 90 degree angle, it took quite a bit of thinking to get the pump kit to assemble the way it did and once assembled, it fits nicely.

The pump install actually requires you to modify the pump housing. Uncut, the pump actually will not fit into the opening at all. The swap also requires you to place 4 new 3/8" diameter holes in the pump mount so they will bolt into the adapter plates.

Prior to finishing up the dry fit on the pump conversion, I had to clean the hull down to bare smc which was not a fun process. The entire bottom deck had multiple layers of paint, gel coat, more paint, and silicone on it. Once that was cut back, the components were marked, drilled and dry fit.

The last 2 issues I ran into do not involve the Rhaas parts, rather the supporting parts. As part of the kit, you need an intake grate from a 750sx. I picked up a solas one because it had a scoop and was reasonably cheap. The first problem is that the scoop is too wide. I ended up taking 0.25" off each side and knocking the sharp edges back on the grate to make it fit. The second issue was that at some point my hull was "repaired" with new threaded inserts. these inserts were not flush with the hull which caused the intake grate to sit proud of the hull. In the process to correct that, one insert fell out of the hole while the other broke flush with the hull. I am still in the process of figuring out a repair for this. I am not thrilled about the inserts being stainless as I have galled bolts before, I have also had them corrode together and get stuck. I would prefer a brass insert but I am not sure if I have any right now.

One final item on the driveline. Currently the exhaust hits the inside of the hull on the left something fierce. I don't really want to cut the hull since I spent quite a bit of time making the inside nice but I will if that is the best option. I am holding off on doing that until I get the pump mounted and the driveshaft installed since I want to make sure the engine alignment is reasonably close before I start hacking.

Bodywork

I also broke out the trusty sanding block and tube and cut back the filler I applied a month or so ago, I was happy to find that it is not full of low spots. I was unhappy to find 15-30 pinholes that I will have to fill before I can throw a coat of paint on it. That's life though, can't complain.

The last remaining items on the bottom of the hull which still need to be addressed are, the rear sponson inserts which were previously riveted on and I drilled out to do the bodywork, and the front tubbies which have no mounting hardware on them.

On the sponsons, I may do something like an aluminum rivnut with a ton of epoxy behind it or since I am planning to do a rear exhaust, I may just carve out some of the foam and epoxy a ufo mount or aluminum plate onto the inside of the hull. To do the other side I would need to plan for a scupper install which may still be an option.

The tubbies originally had flat head screws on them and were just 5200'd to the hull. I removed all the hardware because I needed clearance on the inside for the motor swap. I am considering just glassing over the edges and filling the holes since they are bonded and foamed to the hull already but I am not set on that route.

Time Spent:

8 Hours (remove paint, gelcoat, paint, gelcoat, and silicone. Flip ski repeat process. Mount part, mark holes drill, repeat process. Sand bottom deck, find pinholes, start threads pass out.)

Tools Used:

Broom

Shop Vac

Air Blow Gun

Box Cutter

Oscillating Multitool

Drill and various bits

Spring Loaded Center Punch

Materials Used:

4 sheets of 80 grit sandpaper

PPE Used:

Half Respirator

3M Worktunes Headhones

Percentage of Garage Floor Epoxy Coated

22.2% (no epoxy has been used recently, I need to flip the hull and prepare for more glasswork)

Percentage complete:

35% (I am not super happy with how this stuff currently fits so I may pull it off and redo some of it.)

Sean

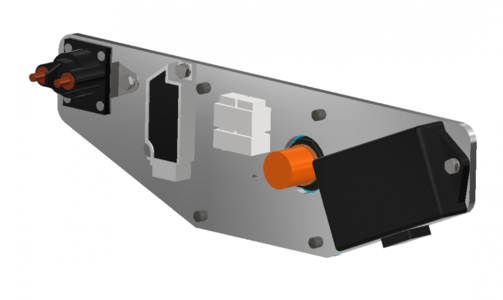

Hull on side, dry fit. If you look close at the steering cable mount, you can see where I had to "relieve it" It is a deceptively simple part in that it looks on first glance that its simple but there is some real work that went into making this work right.

Slightly Better Angle

Holes Marked and Center Drilled. Not shown are the full 0/375" diameter holes and the other cuts needed. Basically you cut the rear ears off (shown on left) and reduce the width by 0.3"ish on each side. I will add a picture once I have it cut per the Rhaas template.

Solas intake grate not fitting, wings for heavy flow days I guess.

Scribed cut lines 0.25" from the edge

And it fits

Damaged and missing bungs, even with these cut back the grate still hangs a bit out into the flow of the shoe. I may mill back the mount a bit to get it to sit further flush with the hull inlet.

Assembled swap minus driveshaft and fastners. It still needs to finesse

Kit minus intake grate and rideplate. I had to cut the shoe mouth piece quite a bit to get it seated all the way so that it wouldn't twist the adapter plate. This would have been less of an issue if I had not been a cheapass and bought the aluminum shoe.

Gaps around where the intake grate mounts. Initially I thought the intake grate mounted to the plastic pieces but it bolts to the pump.

Not sure what I can do to clean up this area, its going to need a lot of work to get a good flow path there. This is really the only area where I am not happy with the kit. The rest I can live with but this is going to require quite a bit of buildup.

All that said, I would buy the kit again. I think it's expensive for the parts you get but you aren't really paying for just the parts, you are paying for all the work that went into getting the system to a point that someone can order the kit and use it without a huge amount of work. I can see that it was a process to get everything right and I can safely say, I would not have done this for myself if I had to start from scratch on it. I would have liked it more if the parts fit better but given the process limitations of the materials, they are close enough. If the parts had been made out of a different material or process, the cost would be too much to consider so I think they did their due diligence on them. I do maintain that the aluminum adapter piece is probably worth the extra cost and I will be ordering one if Rhaas will let me.

Sean