Decided to finally post up a build l have been working for a while now.A new old stock garage find SuperFreak Circus.l've had this hull and deck for over a year now and have just really started working on it since last fall.Then l had shoulder surgery and couldn't lift a piece of carbon.Don't look for a quick build before summer hits,l can't ride probably till Sept or Oct.

l finished building @sportfish258 Circus last year and had all the components to work on mine.l lacked a 155 mag pump which l ended up buying last year,so this ski should be strong once completed.l am making and installing Tem's signature big exhaust pipe under the tray to keep it original.

A few pics to get started.When l got it home:

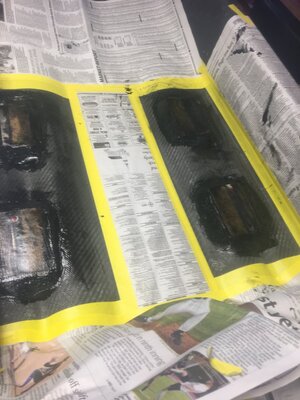

How a Circus starts,a pump ring that has to be bonded the the pump housing area.This has to be Perfect.More so on these hulls because there is no adjustments after installed..The carbon scoop you see at the top of the pic is to force water into the pump,that has to be bonded to the ring.There is also a wing that has to be made that serves as a"top loader"

Just a mock up of things to come

So it's a start and so far so good!

l finished building @sportfish258 Circus last year and had all the components to work on mine.l lacked a 155 mag pump which l ended up buying last year,so this ski should be strong once completed.l am making and installing Tem's signature big exhaust pipe under the tray to keep it original.

A few pics to get started.When l got it home:

How a Circus starts,a pump ring that has to be bonded the the pump housing area.This has to be Perfect.More so on these hulls because there is no adjustments after installed..The carbon scoop you see at the top of the pic is to force water into the pump,that has to be bonded to the ring.There is also a wing that has to be made that serves as a"top loader"

Just a mock up of things to come

So it's a start and so far so good!