You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

155 Pump shoe in Superjet /Wich one

- Thread starter steve711

- Start date

- Location

- PST

I bought a RRP, defiantly less work to make it fit. It is narrower so you won't have to cut the pump tunnel up as much.

Also, there is no transition lip like the JD pump shoe. You'll just need to fair in where the 144 pump shoe lip was to match up to the RRP.

Yes it is more expensive but worth the reduction in hull work.

Also, there is no transition lip like the JD pump shoe. You'll just need to fair in where the 144 pump shoe lip was to match up to the RRP.

Yes it is more expensive but worth the reduction in hull work.

Last edited:

I bought a RRP, defiantly less work to make it fit. It is narrower so you won't have to cut the pump tunnel up as much.

Also, there is no transition lip like the JD pump shoe. You'll just need to fair in where the 144 pump shoe lip was to match up to the RRP.

Yes it is more expensive but worth the reduction in hull work.

I appreciate your comment who helping order the right parts ,much appreciated !

I heard the Waterdawgz to was really easy to fit ,

Thanks

- Location

- PST

I think this part is very similar to the WDK part. I will note that the RRP shoe has about 1 degree more wedge built in to it versus the stock shoe. I had about 8mm of shims on the end to get the shaft square to the bulkhead.I appreciate your comment who helping order the right parts ,much appreciated !

I heard the Waterdawgz to was really easy to fit ,

Thanks

- Location

- PST

I haven't ran it yet, wanted to reinforce the hull before I installed the engine. It's a '96 so it has seen some action. Planning on running a 7/12 Skat to start in a WB2 pump with a ported 760. This will be my first Yamaha SJ (I'm a Kawi guy). Kind of ended up with all the parts minus a hull, so figured I might as well build one.You installed it in a Superjet ? How it perform versus the 144 mm ?

I haven't ran it yet, wanted to reinforce the hull before I installed the engine. It's a '96 so it has seen some action. Planning on running a 7/12 Skat to start in a WB2 pump with a ported 760. This will be my first Yamaha SJ (I'm a Kawi guy). Kind of ended up with all the parts minus a hull, so figured I might as well build one.

Are you taking some pics ?

Thanks

- Location

- PST

Yes, I'll post them this week when I'm back in town.Are you taking some pics ?

Thanks

- Location

- PST

Yes, I'll post them this week when I'm back in town.

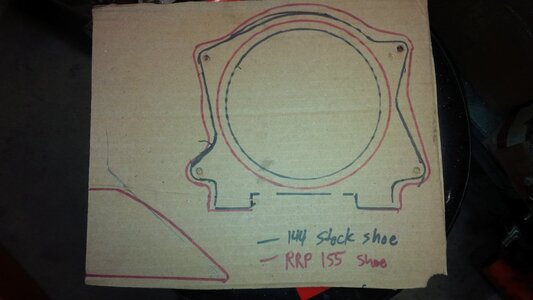

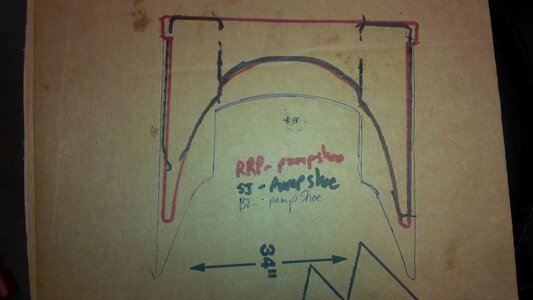

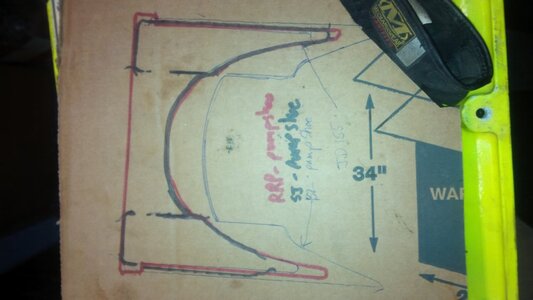

Here are a few showing the difference between the stock 144 SJ and 155 WB2 pump shoe and the RRP.

Attachments

You're putting the 155 pump in a Superjet hull with stock pump tunnel?

I've heard that the pump tunnel is not big enough to feed the 155 pump but no idea if that is actually true.

Yes

If somebody trying it , we could listen his feedback HERE !!

- Location

- PST

That's maybe why WDK machined the seal area ,see WDK description detail:It's tight because of the increase in cast in wedge. I'm going to try cramming it in there over the weekend (pump seal). Here are some more pictures of the pump fitted up. View attachment 365970

''This pump shoe will allow use of the 155mm pump from Yamaha models 1997-1999 GP1200 and 1996-1999 Wave Venture in your SuperJet. Modification to the intake grate necessary. Comes as cast except for seal area which is machined. Clearance for intake grate and mounting holes will need to be done.

- Location

- PST

It's not a matter of the machined surface where the pump mates up (the as cast surfaces are actually quite good). RRP purposely put more wedge in the casting for use in AM hulls is my guess. I don't want more pump angle because this is not getting a trim nozzle. Trying to keep the pump as parallel to 144 pump location as possible.

My focus on this conversion was to see if I could install it with the least about of modifications to the hull and pump (which is what others are going to want). I could easily enlarge/slot the pump mounting brackets and move the pump back slightly and the seal would fit without too much issue (which is what I may end up doing if I can find another suitable seal solution) . In the enlarged picture you can see the gap on the bottom, it is touching on the top. The pump is currently aligned square to the bulkhead and centered in the hole. I am using a B2 driveshaft which is a little more than 1/2" longer than the SJ shaft (right around 27") this puts the mid-shaft about 6-8mm forward. I'm machining the coupler 6mm and adding a 6mm spacer (to keep the standard 19mm mid-shaft offset). This will get me 2-3mm of coupler clearance and doesn't require any engine mount modification. For future builds I will have a driveshaft made with longer splines or 1/4" shorter (once again for this build I'm trying to use off the self parts if possible).

I might just go ahead and buy a JD 155 pump shoe to compare the two. It may actually be easier once the lip is removed.

My focus on this conversion was to see if I could install it with the least about of modifications to the hull and pump (which is what others are going to want). I could easily enlarge/slot the pump mounting brackets and move the pump back slightly and the seal would fit without too much issue (which is what I may end up doing if I can find another suitable seal solution) . In the enlarged picture you can see the gap on the bottom, it is touching on the top. The pump is currently aligned square to the bulkhead and centered in the hole. I am using a B2 driveshaft which is a little more than 1/2" longer than the SJ shaft (right around 27") this puts the mid-shaft about 6-8mm forward. I'm machining the coupler 6mm and adding a 6mm spacer (to keep the standard 19mm mid-shaft offset). This will get me 2-3mm of coupler clearance and doesn't require any engine mount modification. For future builds I will have a driveshaft made with longer splines or 1/4" shorter (once again for this build I'm trying to use off the self parts if possible).

I might just go ahead and buy a JD 155 pump shoe to compare the two. It may actually be easier once the lip is removed.

It's not a matter of the machined surface where the pump mates up (the as cast surfaces are actually quite good). RRP purposely put more wedge in the casting for use in AM hulls is my guess. I don't want more pump angle because this is not getting a trim nozzle. Trying to keep the pump as parallel to 144 pump location as possible.

My focus on this conversion was to see if I could install it with the least about of modifications to the hull and pump (which is what others are going to want). I could easily enlarge/slot the pump mounting brackets and move the pump back slightly and the seal would fit without too much issue (which is what I may end up doing if I can find another suitable seal solution) . In the enlarged picture you can see the gap on the bottom, it is touching on the top. The pump is currently aligned square to the bulkhead and centered in the hole. I am using a B2 driveshaft which is a little more than 1/2" longer than the SJ shaft (right around 27") this puts the mid-shaft about 6-8mm forward. I'm machining the coupler 6mm and adding a 6mm spacer (to keep the standard 19mm mid-shaft offset). This will get me 2-3mm of coupler clearance and doesn't require any engine mount modification. For future builds I will have a driveshaft made with longer splines or 1/4" shorter (once again for this build I'm trying to use off the self parts if possible).

I might just go ahead and buy a JD 155 pump shoe to compare the two. It may actually be easier once the lip is removed.

It's tight because of the increase in cast in wedge. I'm going to try cramming it in there over the weekend (pump seal). Here are some more pictures of the pump fitted up. View attachment 365970

Nice général info man ,

About the same set up but mine is a Gp1200

155mm pump with a trim nozzle , need some tread x4 to hold the bolts pump(4) together

I’ll put a Superjet shaft or modified another one for the exact lenght i need .

Ready to order now for the Black Friday deal

155 Prop , seal, And Pump shoe

Curious to see the JD155

Nice info ! We keep in touch

- Location

- PST

I ordered a JD155 shoe, I'll do a comparison once it arrives.

- Location

- PST

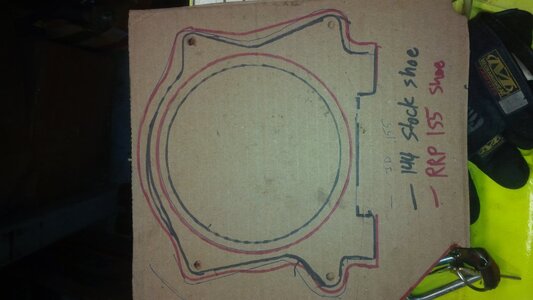

I took a few pics of the JD155 pump shoe. Size wise it is similar to the RRP overall. I'll post more comments later.

Attachments

I took a few pics of the JD155 pump shoe. Size wise it is similar to the RRP overall. I'll post more comments later.