- Location

- Appleton, WI

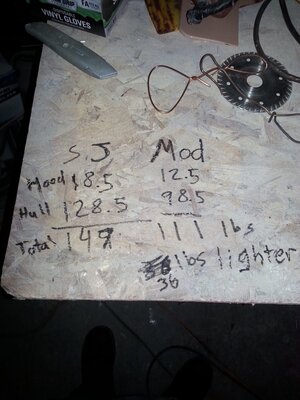

Now that I've been building this ski for a couple of months now I've decided to post some pictures and comments on the build. First off the first is a picture of some ski's that Jakobi86 and myself built last spring when we first got into this sport. Just a couple of SN's that got stripped, cleaned, painted and turfed. All work done by us. Then later last summer I picked this ski up from a member on the x with unsure plans for its future but I mostly bought it for the parts list. It was a 90 SN with 701, b pipe, ada head, 9/15 hooker, msd enhancer, AC aluminum pole, jetworks flow control valve, and footholds. After getting it home and digging into it a little the hull was in pretty rough shape and at one point almost threw the whole thing in the trash and was just going to swap all the parts into the my blue ski. Well before that happened I figured i try one of these SN builds as I love building things/working in the garage yada yada. So my intentions were to shortened, refoam, reinforce, rocker, and lower the hood. I am going to start by posting pics of the progress in progression with little description because I don't want to spent a ton of time putting this thread together. Before I start that I need to give a big thanks to Jakobi86 for letting me do the entirety of this build in his garage!

First pics in this post include the original ski, and cutting up the tray. Mind you I am no professional fiberglasser. At that this project was the first time I laid fiber glass in my life!

First pics in this post include the original ski, and cutting up the tray. Mind you I am no professional fiberglasser. At that this project was the first time I laid fiber glass in my life!