I think I looked hard enough and didn't see 3/4" check valves anywhere for bilge pump exits. I know you can loop up and over, but it would be nice to keep hoses short and direct if possible for engine bay cleanliness. I tried some plumbing places and only found heavy brass with strong springs on the ball. These would also need barb adapters which is too much adapting. Also looked at sump, irrigation, and other PVC check valve options, however they were all large, like 1 1/4" and up. So I came accross this idea. Let me know your opinions . Please be kind.

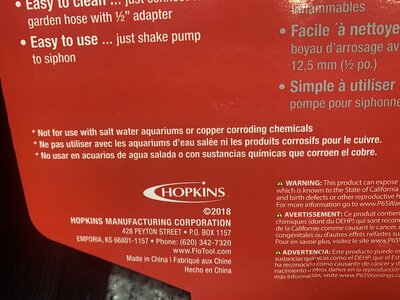

At my local automotive store. (for local canadians, Canadian Tire) they have these things as seen on TV in pic 1. It's the cheesy shake to start siphoning fuel out a car, lawnmower, power sport machine , etc. hose.

not for salt water use!!

Its perfect on one side to use the existing hose to attached to your bilge outlet barb. The other side has a lip and I just sanded/grinded it down to fit the 3/4 " bilge hose and then I sleeved over a bit of clear heat shrink tube first . Then sleeved over the 3/4" plastic bilge hose . This gives a non slippery surface for the short overlap of hose to not slip off easily. Clamped it up and installed. In my case thats 2- 3/4" holes that wont be taking on water in my KRASH hull.

I am trying this idea with running 2 bilge pumps as well as my versiplug. I have the one bilge pump located in the regular spot near the mid shaft. and I installed a mini bilge pump down the built in tunnel on the port side of the rear of the hull . This is where the old scupper / new versiplug is installed. For me, this pump will be an alarm indicating when the versiplug is leaking or not working. We'll see.

At my local automotive store. (for local canadians, Canadian Tire) they have these things as seen on TV in pic 1. It's the cheesy shake to start siphoning fuel out a car, lawnmower, power sport machine , etc. hose.

not for salt water use!!

Its perfect on one side to use the existing hose to attached to your bilge outlet barb. The other side has a lip and I just sanded/grinded it down to fit the 3/4 " bilge hose and then I sleeved over a bit of clear heat shrink tube first . Then sleeved over the 3/4" plastic bilge hose . This gives a non slippery surface for the short overlap of hose to not slip off easily. Clamped it up and installed. In my case thats 2- 3/4" holes that wont be taking on water in my KRASH hull.

I am trying this idea with running 2 bilge pumps as well as my versiplug. I have the one bilge pump located in the regular spot near the mid shaft. and I installed a mini bilge pump down the built in tunnel on the port side of the rear of the hull . This is where the old scupper / new versiplug is installed. For me, this pump will be an alarm indicating when the versiplug is leaking or not working. We'll see.