- Location

- NYC/Long Island

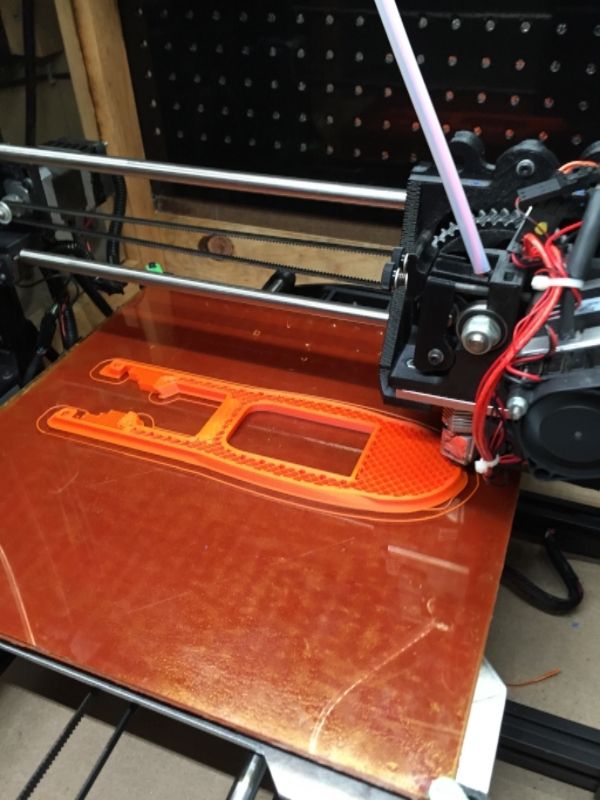

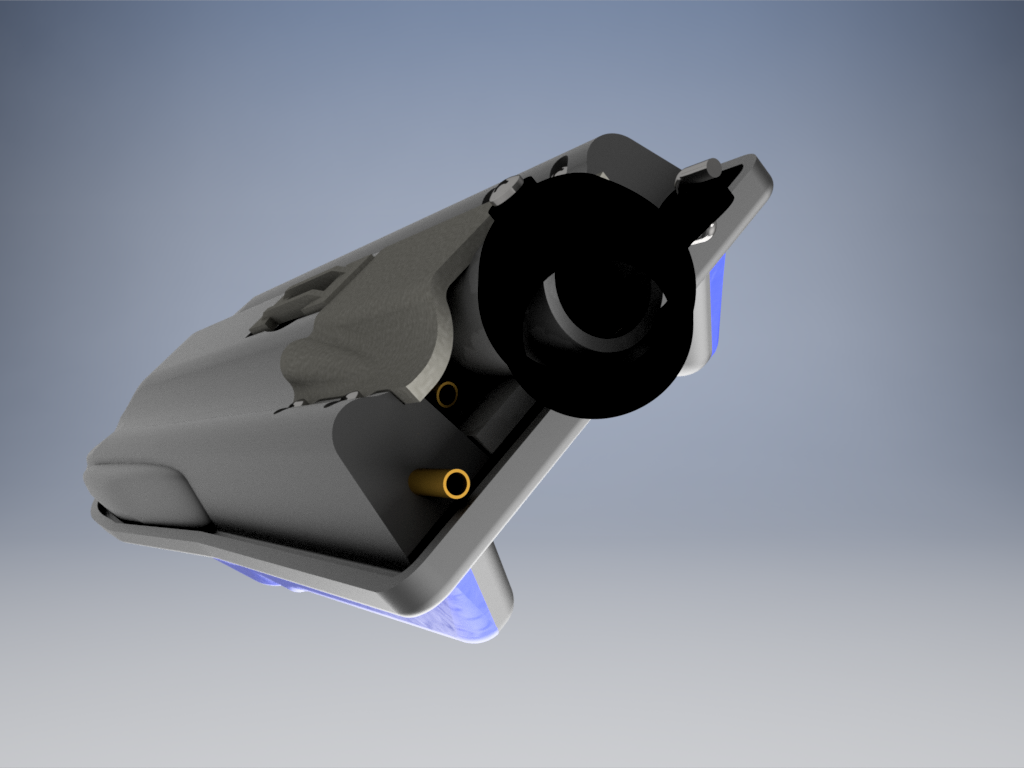

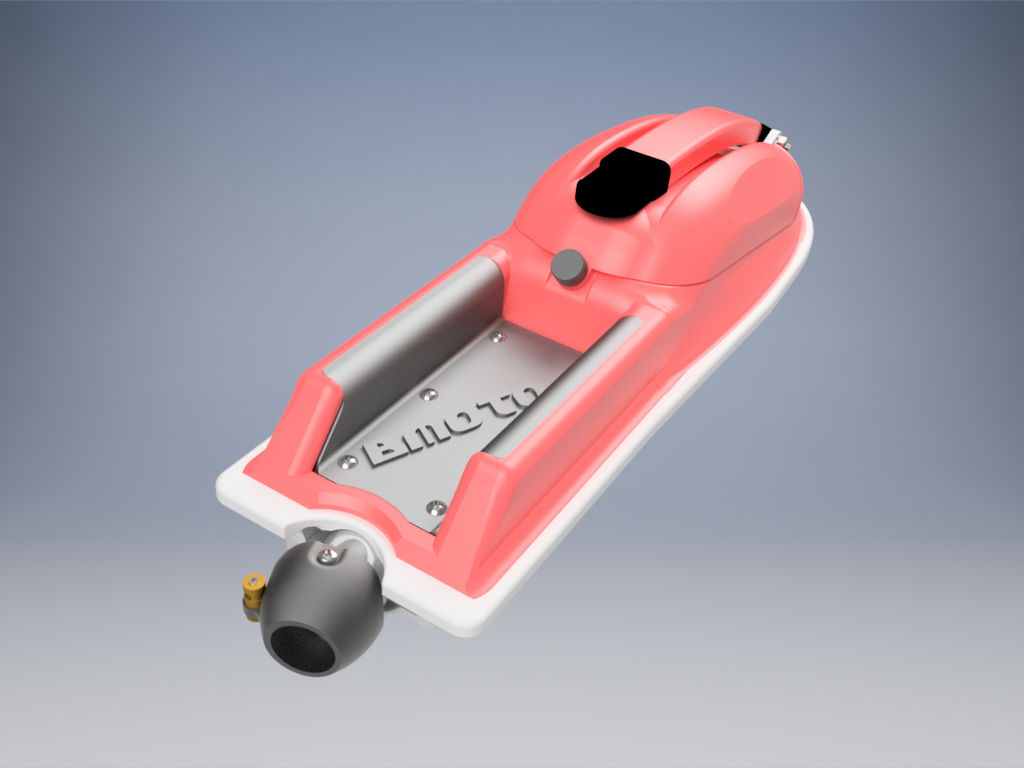

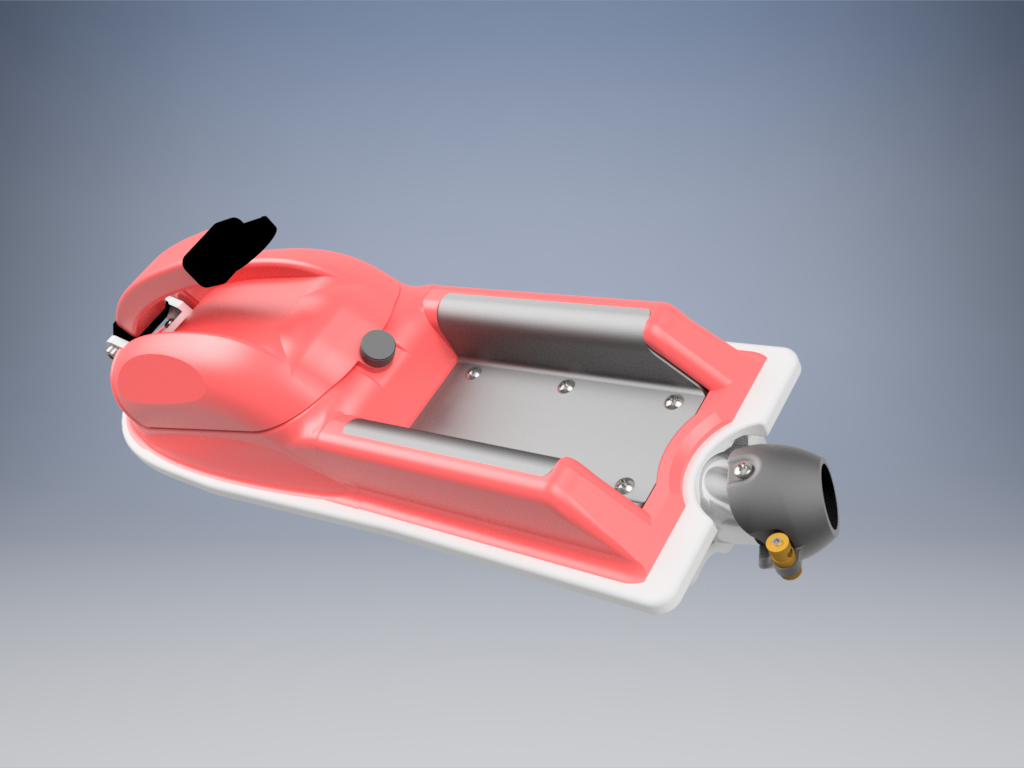

Since I began making the desktop surfer, I had always wanted to make it RC with a DC motor. A few people suggested some components I can use and now I am really considering it. I want to use the existing model and scale it up ≈ 200%. That makes it ≈ 11" long, and 3.6" wide.

Do you all remember the tech deck's of the 90's? That is the idea behind this. A small RC jet ski that is capable of multiple backflips, fist pumping, and world final worthy action that you can compete with your friends and annoy your family at your next pool party.

There are many jet drive assemblies already available such as this one:

http://www.ebay.com/itm/2-pcs-New-N...416158?hash=item2ed7c39a9e:g:0T0AAOSwxYxUv1cg

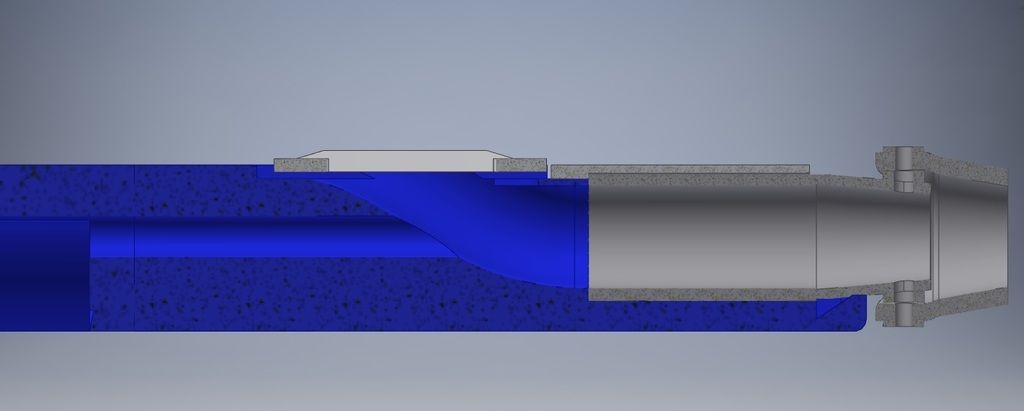

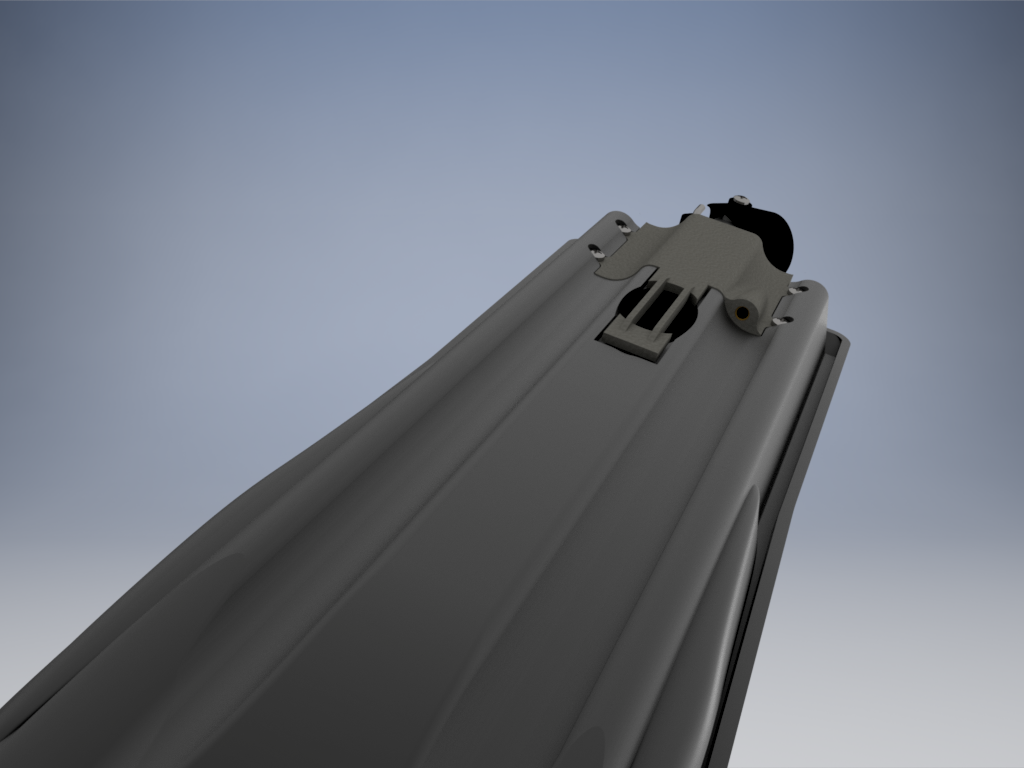

What I dislike is that they are nearly 4" long. Why am I going to bother when I already have a pretty damn good pump tunnel on the existing model? So I want to make my own that is a close replica to a Superjet drivetrain.

For the RC experts here: I don't understand how RC jet boats are sealing their driveshaft? I've seen a brass sleeve with a nylon insert so a 3mm driveshaft can go through. I would think that would be sufficient for sealing, but what about friction? I think that would get extremely hot and load the motor.

The driveshaft/pump assembly is the largest hurdle right now. I am sure at that scale I can find room for a DC motor/battery/electronics.

I will be documenting the entire build here. If you haven't checked out the current (mini sized of this project) 'Desktop Surfers' check it out here: http://www.bmotoshop.com/collections/personal-watercraft/products/desktop-surfer-jet-ski-model

Do you all remember the tech deck's of the 90's? That is the idea behind this. A small RC jet ski that is capable of multiple backflips, fist pumping, and world final worthy action that you can compete with your friends and annoy your family at your next pool party.

There are many jet drive assemblies already available such as this one:

http://www.ebay.com/itm/2-pcs-New-N...416158?hash=item2ed7c39a9e:g:0T0AAOSwxYxUv1cg

What I dislike is that they are nearly 4" long. Why am I going to bother when I already have a pretty damn good pump tunnel on the existing model? So I want to make my own that is a close replica to a Superjet drivetrain.

For the RC experts here: I don't understand how RC jet boats are sealing their driveshaft? I've seen a brass sleeve with a nylon insert so a 3mm driveshaft can go through. I would think that would be sufficient for sealing, but what about friction? I think that would get extremely hot and load the motor.

The driveshaft/pump assembly is the largest hurdle right now. I am sure at that scale I can find room for a DC motor/battery/electronics.

I will be documenting the entire build here. If you haven't checked out the current (mini sized of this project) 'Desktop Surfers' check it out here: http://www.bmotoshop.com/collections/personal-watercraft/products/desktop-surfer-jet-ski-model

Last edited: