Jcary85

Site Supporter

- Location

- Glenmoore pa

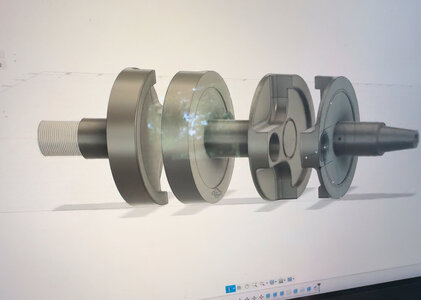

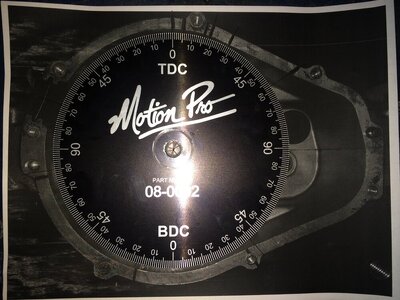

Does anyone happen to know how many degrees the crank keyway is offset from cylinder 1 TDC? I designed a crank and this is the last thing I need to add. Idk why genius Yamaha didn’t just line it up with…. Anything. Figured I’d ask before I go figure out how to measure this…