- Location

- New Orleans

I bought a EME Ski with a EME 1000 in it two years ago. Due to work and various issues I only rode it twice. It ran strong and was fun those days. No hard crashes, no sinking, great power. I cleaned it nicely and put it away for just over a year. It was fogged.

I put fresh fuel lines and fuel in it last week and it started right up. It didn't idle well like it did before - it idled very high and a little rough but I figured that was air in the fuel lines (I could see some bubbles). I headed for the lake that afternoon and when I got it in the water it wouldn't turn all the way over when I tried to start it. I was thinking that maybe my starter had cooked...

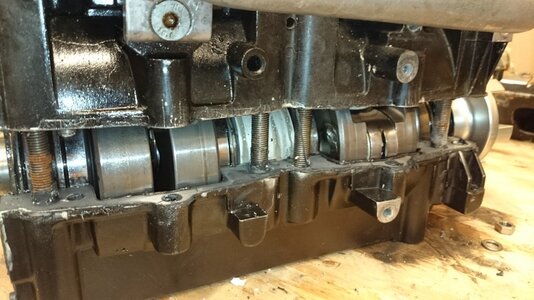

I went to work for a week and ordered a OEM starter. I was going to change it out today. I pulled my tank and the flywheel cover off just to look around to make sure all of the teeth were there and the bendix looked OK. It was bone dry in the flywheel case and everything seemed to be in order. I pulled the plugs, and they looked OK - oily, but OK. With the plugs out I turned the flywheel by hand. The motor turns smooth and easy. As I was looking around I noticed what appeared to be a slug of water in my pulse line! It was. I unhooked the carb side of the line and lowered it below the block and some water ran out. I cranked the flywheel by hand and more water would shoot out with each pulse. I probably got at least a cup of water out of the pulse line before I stopped....

What is the next step here? I didn't get water in the engine due to a major mishap so I have a case leak somewhere? I should do a case leakdown test next and see if I can find a leak? Do I need to split the whole case and look at the crank for rust, etc?

I put fresh fuel lines and fuel in it last week and it started right up. It didn't idle well like it did before - it idled very high and a little rough but I figured that was air in the fuel lines (I could see some bubbles). I headed for the lake that afternoon and when I got it in the water it wouldn't turn all the way over when I tried to start it. I was thinking that maybe my starter had cooked...

I went to work for a week and ordered a OEM starter. I was going to change it out today. I pulled my tank and the flywheel cover off just to look around to make sure all of the teeth were there and the bendix looked OK. It was bone dry in the flywheel case and everything seemed to be in order. I pulled the plugs, and they looked OK - oily, but OK. With the plugs out I turned the flywheel by hand. The motor turns smooth and easy. As I was looking around I noticed what appeared to be a slug of water in my pulse line! It was. I unhooked the carb side of the line and lowered it below the block and some water ran out. I cranked the flywheel by hand and more water would shoot out with each pulse. I probably got at least a cup of water out of the pulse line before I stopped....

What is the next step here? I didn't get water in the engine due to a major mishap so I have a case leak somewhere? I should do a case leakdown test next and see if I can find a leak? Do I need to split the whole case and look at the crank for rust, etc?