I started my first custom build in January of this year. I have a bunch of pictures of the build so I figured I would start a build thread and get some feedback. I'll post a few pictures a day until I'm caught up. So here it goes...

A friend of mine designed and built 3 custom hulls a few years ago. One of the hulls was never built so I stripped my '01 Superjet, sold the SJ hull & pole, and bought the custom hull from my friend.

The Idea was to take the guts from my SJ and build the hull up with those. I was hoping to build a flatwater ski that I could learn to get inverted on.

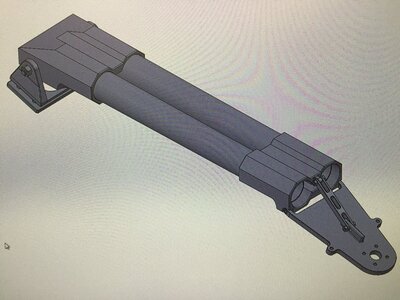

The only thing I didn't have was a pole. This is when I got the idea to design and built my own custom pole. I work as a Toolmaker at a local shop, and they don't mind if we use their machines off the clock for home projects, so I started to design a custom pole. I did most of the design in Solidworks. I used my imagination and combined a few features from various poles on the market. It took me the better part of my lunch breaks for a few weeks to come up with a design that I liked.

Below are some pictures of the hull the day I picked it up, and a few of the Solidworks pole design.

A friend of mine designed and built 3 custom hulls a few years ago. One of the hulls was never built so I stripped my '01 Superjet, sold the SJ hull & pole, and bought the custom hull from my friend.

The Idea was to take the guts from my SJ and build the hull up with those. I was hoping to build a flatwater ski that I could learn to get inverted on.

The only thing I didn't have was a pole. This is when I got the idea to design and built my own custom pole. I work as a Toolmaker at a local shop, and they don't mind if we use their machines off the clock for home projects, so I started to design a custom pole. I did most of the design in Solidworks. I used my imagination and combined a few features from various poles on the market. It took me the better part of my lunch breaks for a few weeks to come up with a design that I liked.

Below are some pictures of the hull the day I picked it up, and a few of the Solidworks pole design.