- Location

- Rexburg, ID

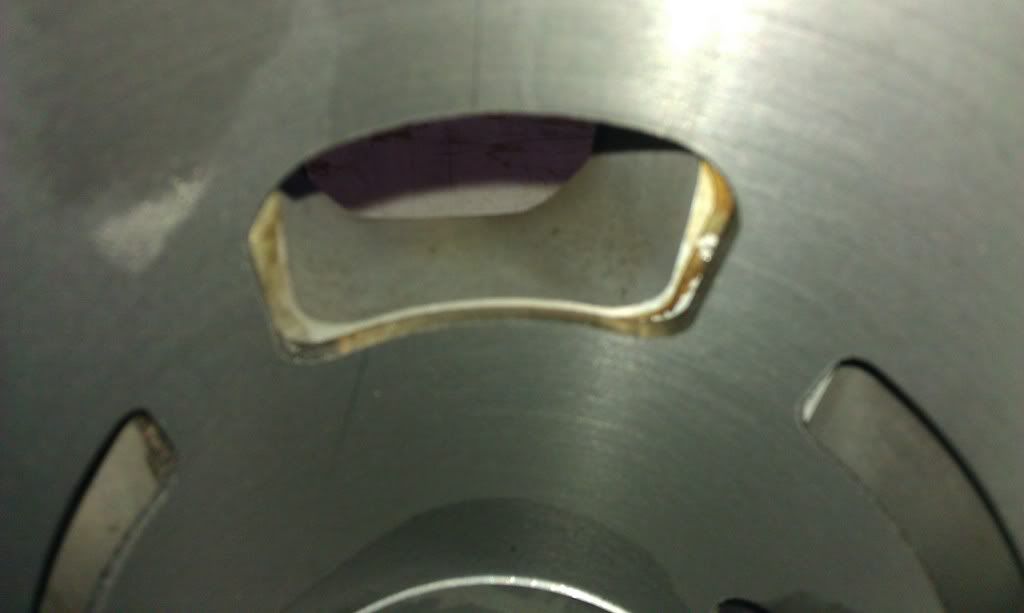

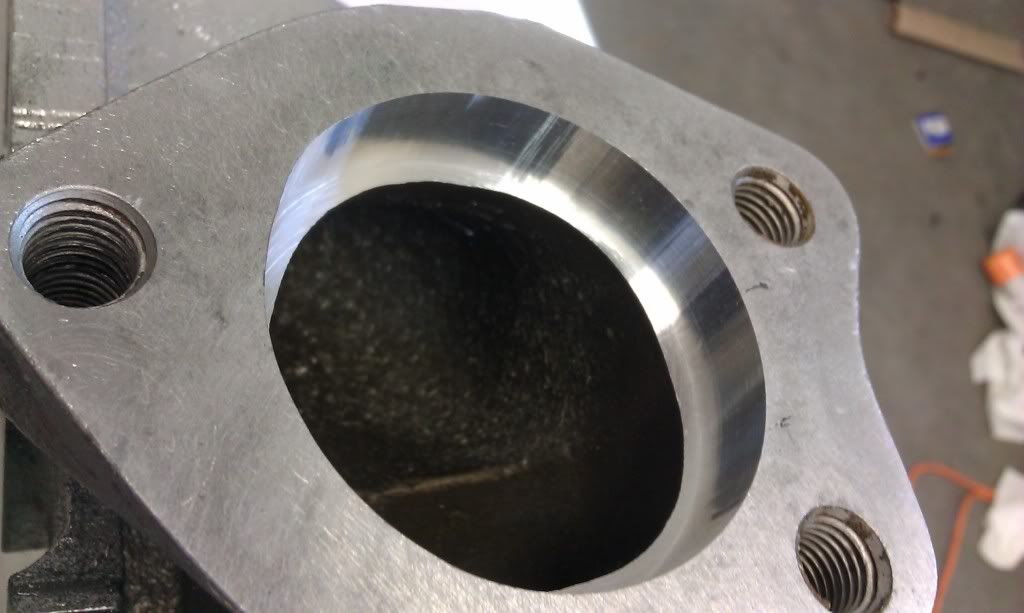

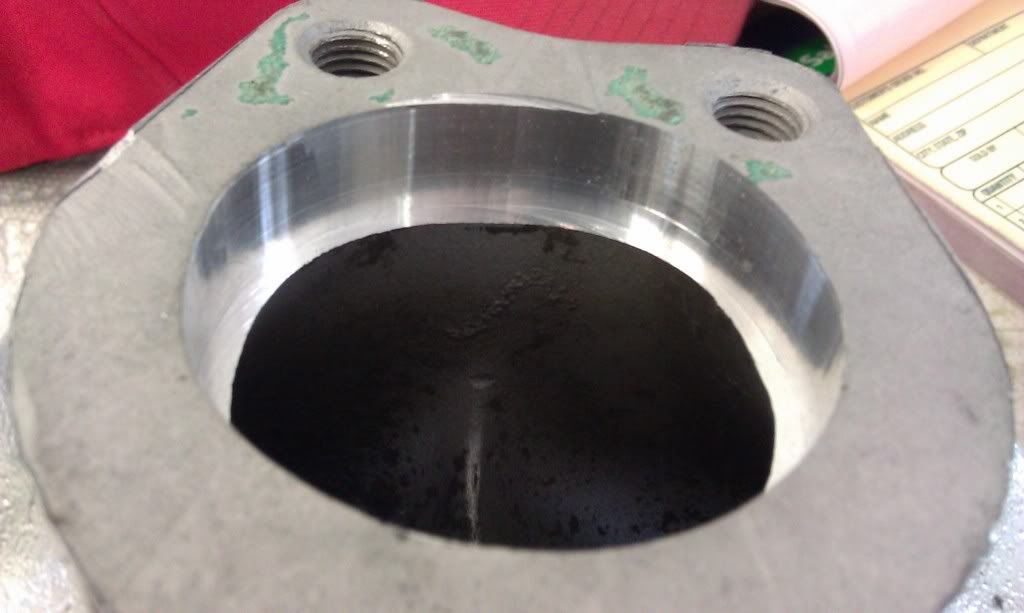

Last year running a ported 701 with R&D dry pipe was fun. But alas I want more. So Blowsion and all their dang catalogs they send you just sit around and temp. So I have since ordered up their 850 sleeves and pistons.

The 98 sj hull i have was painted rather well and was originally built for racing. I guess that's why the hood has flames on it. But I'm not a flamer kind of guy so I wanted to repaint it. I'm leaving the turf on because its mint and I don't want to spend another bill redoing it just to paint under something you will never see.

Stripping the hull sucked.... steering cables are a pita to get out.

I am trying my luck at reinforcing the hull. Mostly because last year at the crystal clear waters of manBear lake Idaho I did a nose stab. Who would have thought that in five feet of water you would hit the rock on the bottom. So that cracked the nose a bit and blistered the inside of the hull.

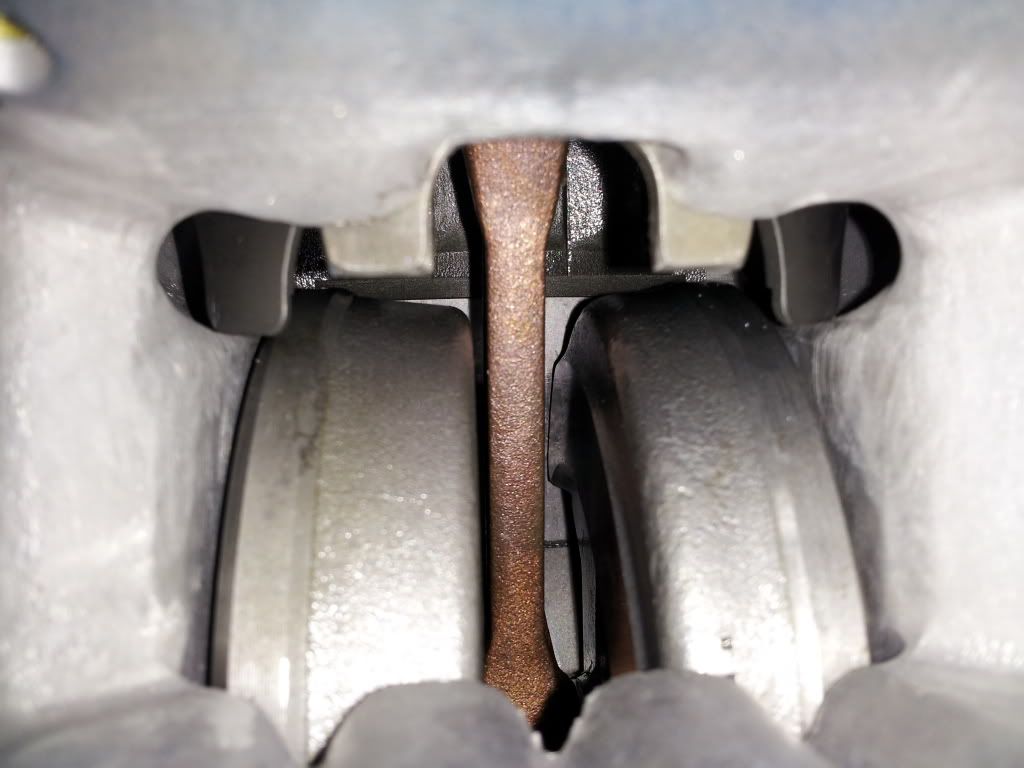

I did like about 6 layers on the handle pole mount and i don't even know how many on the nose. Plus two strips per side on the deck seems. I wanted to used the 3'' wide stuff because i thought it would be easier to manage and jam in the crack. I'm also using 3:1 epoxy resin from the us composite store. Go ahead pick and make fun of my first reinforcement job (please tell me what I'm doing wrong). I am also at a lot for what to do about the bottom of the inside of the hull. I would like to make it cleaner looking but besides sand paper nothing seems to clean it. This is the first run and I plan on going over the whole sides when this sets up tomorrow with wide cut to fit pieces. Would two layers on the sides be enough?

? as my ski sits it weighs 155.X lbs with all the bottom stuff. Pump/plate/grate/shaft/prop/bearing housing ect. Does this sound about right? or is the hull chuck full of water?

[FONT=arial, helvetica, 'sans serif']

[/FONT]

[FONT=arial, helvetica, 'sans serif']

[/FONT]

[FONT=arial, helvetica, 'sans serif']

[/FONT]

[FONT=arial, helvetica, 'sans serif']

[FONT=arial, helvetica, 'sans serif']

[/FONT]

The 98 sj hull i have was painted rather well and was originally built for racing. I guess that's why the hood has flames on it. But I'm not a flamer kind of guy so I wanted to repaint it. I'm leaving the turf on because its mint and I don't want to spend another bill redoing it just to paint under something you will never see.

Stripping the hull sucked.... steering cables are a pita to get out.

I am trying my luck at reinforcing the hull. Mostly because last year at the crystal clear waters of manBear lake Idaho I did a nose stab. Who would have thought that in five feet of water you would hit the rock on the bottom. So that cracked the nose a bit and blistered the inside of the hull.

I did like about 6 layers on the handle pole mount and i don't even know how many on the nose. Plus two strips per side on the deck seems. I wanted to used the 3'' wide stuff because i thought it would be easier to manage and jam in the crack. I'm also using 3:1 epoxy resin from the us composite store. Go ahead pick and make fun of my first reinforcement job (please tell me what I'm doing wrong). I am also at a lot for what to do about the bottom of the inside of the hull. I would like to make it cleaner looking but besides sand paper nothing seems to clean it. This is the first run and I plan on going over the whole sides when this sets up tomorrow with wide cut to fit pieces. Would two layers on the sides be enough?

? as my ski sits it weighs 155.X lbs with all the bottom stuff. Pump/plate/grate/shaft/prop/bearing housing ect. Does this sound about right? or is the hull chuck full of water?

[FONT=arial, helvetica, 'sans serif']

[/FONT]

[FONT=arial, helvetica, 'sans serif']

[/FONT]

[FONT=arial, helvetica, 'sans serif']

[/FONT]

[/FONT]