- Location

- marion ohio

Just like the title says would like some good info on how to repitch a prop. I don't want tosend it to impro's. I've heard they take for ever. I've gotta 7/18 and I need more low end.

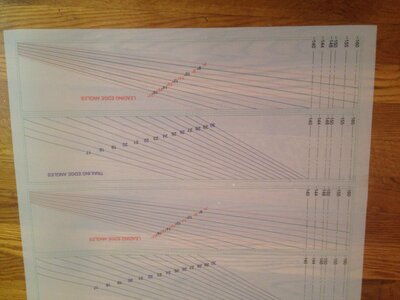

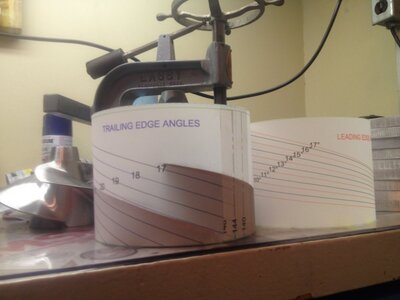

There is a ton of info over on greehulk. There is a guy that even had a DIY hitch mount prop bender so you can test and tune at the lake. There is also a .pdf floating around that you can print out yourself, however, it's not useable b/c of how it's formatted on 8.5x11, I couldn't get it to come out correctly on 11x17. Ended up makeing some on heavy gauge 22" translucent Mylar. I have a few extra if anyone wants them. Asking $10 and ship/pp. PM for details, not trying to derail the thread just listing options. View attachment 247175View attachment 247176

It's like bending a wire over and over. It gets softer. Impros says the same thing only re pitch 3 times max. Although knowing my luck, you were being sarchastic and I misread it and choked lmao! Also you can only re pitch so far off of your root angles as I understand.metal does not soften from bending...they harden

Just send it to the guy that pitches props for me and NVjay. http://www.wcporting.com/The guy that re pitches for me also mentioned that the prop will start to soften after 3 bends (re pitches) Food for thought.