- Location

- Lake Lotawana, MO

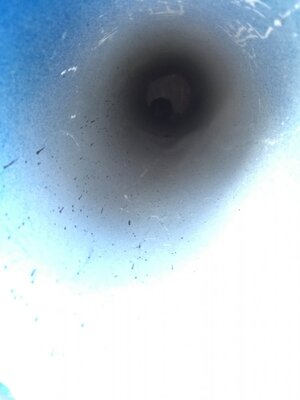

I just picked up a new ski that was cut for a scupper however it was cut too big. Instead of trying to make it work, I am just going to fill the entire hole since it has a bilge and I will be riding on a small lake. My idea was to use polycarbonate plexiglass and 5200 to initially seal the hole. Then once that is dry, go back and fiberglass over the top of that using an epoxy resin and heavy mat. I plan on repeating this for the hole inside the hull. My brother thinks I need to use a rising foam he used to back fill his footholds but couldn't remember what he used. Something from Blowsion. Any suggestions would be greatly appreciated! Thanks!