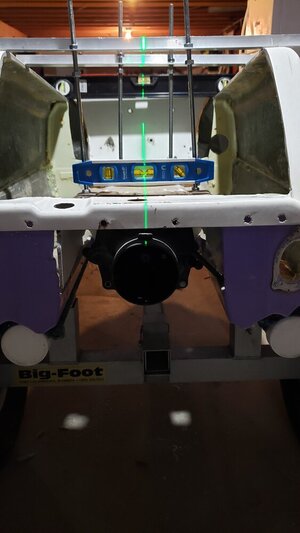

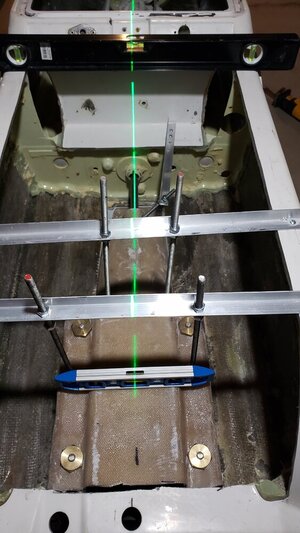

Finally making enough progress to post something on this, so here goes.

I picked up an FX-1 hull a year or so ago with a handful of goodies. Probably over-paid slightly, but I've wanted an FX project for a while. This is my first 'big' project involving fiberglass, hence the 'over my head'. Please let me know if you see anything stupid going on.

To my knowledge this thing came with Tom's tubbies, wide tray, pump tunnel, and hood liner. It also came with a fiberglass ride plate... I'm not sure if Tom made fiberglass ride plates at one point? Anyways...

As received (after a light cleaning):

I picked up an FX-1 hull a year or so ago with a handful of goodies. Probably over-paid slightly, but I've wanted an FX project for a while. This is my first 'big' project involving fiberglass, hence the 'over my head'. Please let me know if you see anything stupid going on.

To my knowledge this thing came with Tom's tubbies, wide tray, pump tunnel, and hood liner. It also came with a fiberglass ride plate... I'm not sure if Tom made fiberglass ride plates at one point? Anyways...

As received (after a light cleaning):

Attachments

Last edited:

![20220511_162715[1].jpg 20220511_162715[1].jpg](https://www.x-h2o.com/data/attachments/340/340187-3601f303eda63bd879dbadc44490cdfa.jpg)

![20220506_232400[1].jpg 20220506_232400[1].jpg](https://www.x-h2o.com/data/attachments/340/340188-073a96f2c78b191b0c0c1af1d8f5531f.jpg)