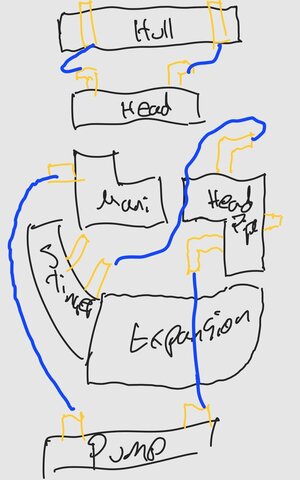

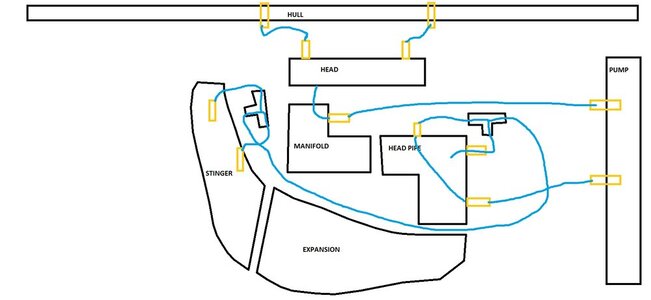

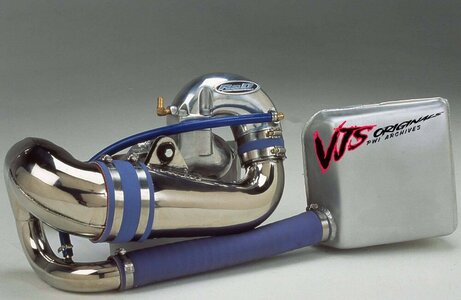

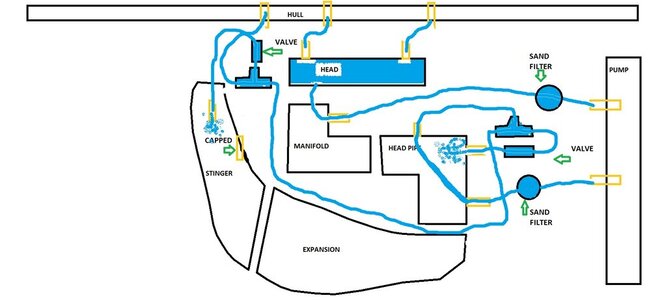

Can anybody shed some light on which pipe this is and maybe help me get it set up? Check out the diagram I drew up, it's my best guess and a starting point of how I figured it should be hooked up. But, really I have no idea as I'm left with the two stinger fittings and the straight fitting unused.

The two 90 degree fittings on the head pipe are into the same water jacket, the straight fitting is an injection into the head pipe exhaust chamber. Then I'm left with the two in the stinger.

Any advice is appreciated, the guy who built the motor and sold the setup to me said I should be running 3 pissers as well, but I don't get how.

The two 90 degree fittings on the head pipe are into the same water jacket, the straight fitting is an injection into the head pipe exhaust chamber. Then I'm left with the two in the stinger.

Any advice is appreciated, the guy who built the motor and sold the setup to me said I should be running 3 pissers as well, but I don't get how.