Hi All

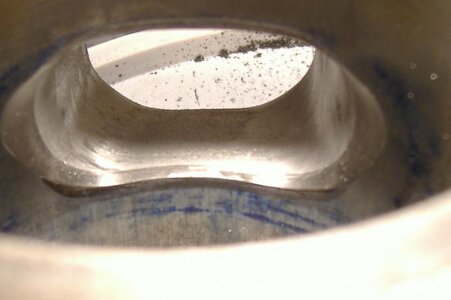

Got my template this week and made a start on the porting template is not the same as the one on the Tech FaQ Posts its the superstock freestyle new one

Tell me what you think ,am i on the right track is my taper to long, should i cut more out, the template is for a superjet 701cc but my one is being bored out to 760

Please tell me if you think i need to anything, any help would be good.

Got my template this week and made a start on the porting template is not the same as the one on the Tech FaQ Posts its the superstock freestyle new one

Tell me what you think ,am i on the right track is my taper to long, should i cut more out, the template is for a superjet 701cc but my one is being bored out to 760

Please tell me if you think i need to anything, any help would be good.