So bought this on craigslist kid didn’t know anything about engine other then it needed to have the carb tuned. I tested compression 150 psi each cylinder so I bought it. Get the ski to the lake tune it ride it and its running good for a while then bogs on top end. Took the ski home pulled head off it had 82mm 32cc domes rated at 210psi so engine was blown up!. Well after finding that out there was 2 screw makes imprinted on top of one piston well those came from the reed block. So I pulled everything out and decided it time to rebuild the engine and hull. So this is where I am at on it and want to do.

1. Lowered stock hood and did the (YAMASLUT) mod for hood liner

2. Carbon fiber layer on bottom of hull and vacuum bagged

3. De-foamed tray and filled bond line

4. Re-constructing water line and added trim cable line plus dual cooling line plus one-way valve

5. Sealing bottom of tray and then going over it with flex seal also dropping exhaust tube down a little bit

6. Shortened rear of hull 3"

7. Using EPS R-TECH in tray instead of 2 part foam

8. Adjustable BOB foot holds and reinforce inside of gunwale with 1708 knytex+3/4 mat backing

9. Grinded ribs in the bilge and going to do reinforcing with 1708

10. Reshape front of nose and possible move pole bracket forward but not sure

11. Trim outer lip

12. Rocker nose maybe

13. Paint guards red Porsche color

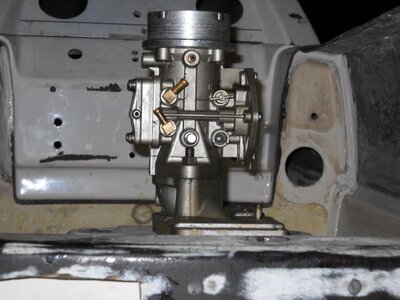

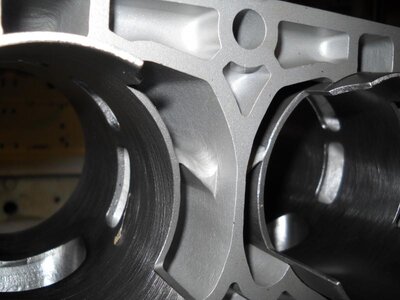

Since the motor was shot and 6m6 cases I ended up contacting Chris (Jet Maniac) he also have super quality work and the prices are right. I bought a ported top end kit with an 83mm bore and 61x cases wet jet manifold true/welded crank and other little things. The ski already had b-pipe dg water box and pro-cool head and hi-performance 44sbn here’s some pictures of what I’ve done so far. would love to hear other's opinions.

1. Lowered stock hood and did the (YAMASLUT) mod for hood liner

2. Carbon fiber layer on bottom of hull and vacuum bagged

3. De-foamed tray and filled bond line

4. Re-constructing water line and added trim cable line plus dual cooling line plus one-way valve

5. Sealing bottom of tray and then going over it with flex seal also dropping exhaust tube down a little bit

6. Shortened rear of hull 3"

7. Using EPS R-TECH in tray instead of 2 part foam

8. Adjustable BOB foot holds and reinforce inside of gunwale with 1708 knytex+3/4 mat backing

9. Grinded ribs in the bilge and going to do reinforcing with 1708

10. Reshape front of nose and possible move pole bracket forward but not sure

11. Trim outer lip

12. Rocker nose maybe

13. Paint guards red Porsche color

Since the motor was shot and 6m6 cases I ended up contacting Chris (Jet Maniac) he also have super quality work and the prices are right. I bought a ported top end kit with an 83mm bore and 61x cases wet jet manifold true/welded crank and other little things. The ski already had b-pipe dg water box and pro-cool head and hi-performance 44sbn here’s some pictures of what I’ve done so far. would love to hear other's opinions.