sfab

X

- Location

- Canada, QC

Hi folks!

First, id like to introduce my self to you. My name is Jonathan, i live in canada (...) im pretty new to the PWC scene but ive been into the world of mecanics and electronics since im 8. Ive build some nice projects over the years, including go-karts, go-peds, cars, ect... blah blah blah, -insert a couples of ennoying autobiographic lines- .... lol

heres the deal: ive bought a square nose superjet 1995 in 2006 which was in good shape with a couple of nice mods on it. the ski was kinda powerful but did not pack enough "punch". im a fat f*cker (235) so i need something powerful enough to get my out of the water!:biggthumpup:

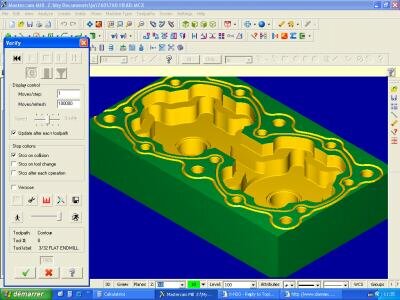

i decided to build a big bore 61x with some homebrew performance parts that i will design and machine all by myself. ive ordered some BB sleeve for NW Sleeve and a sets of 85.5mm wiseco pistons. i thougth about buying a girdled head from some hi-perf cie but i was tempted to make my own. Took some measurements on my stock head, checked a couple of pics and infos of some girdled heads on the net and came with this design:

i didnt bring the cam to the shop as ive planned so i got no pics of the fabrication but got some nice finished ones:

i will try to keep this "log" updated and post pics of the building progress. the next step is to bore the case for the NW sleeves, remove the old sleeves from the cylinder and bore it to the size of the new one. i will also design the domes which is pretty hard to figured out with all the contradictions about squish relief and angle, shape of the combustion chamber... ill try my best to not blow this engine!! LOL i know for sure the compression must be between 170-190lbs.

First, id like to introduce my self to you. My name is Jonathan, i live in canada (...) im pretty new to the PWC scene but ive been into the world of mecanics and electronics since im 8. Ive build some nice projects over the years, including go-karts, go-peds, cars, ect... blah blah blah, -insert a couples of ennoying autobiographic lines- .... lol

heres the deal: ive bought a square nose superjet 1995 in 2006 which was in good shape with a couple of nice mods on it. the ski was kinda powerful but did not pack enough "punch". im a fat f*cker (235) so i need something powerful enough to get my out of the water!:biggthumpup:

i decided to build a big bore 61x with some homebrew performance parts that i will design and machine all by myself. ive ordered some BB sleeve for NW Sleeve and a sets of 85.5mm wiseco pistons. i thougth about buying a girdled head from some hi-perf cie but i was tempted to make my own. Took some measurements on my stock head, checked a couple of pics and infos of some girdled heads on the net and came with this design:

i didnt bring the cam to the shop as ive planned so i got no pics of the fabrication but got some nice finished ones:

i will try to keep this "log" updated and post pics of the building progress. the next step is to bore the case for the NW sleeves, remove the old sleeves from the cylinder and bore it to the size of the new one. i will also design the domes which is pretty hard to figured out with all the contradictions about squish relief and angle, shape of the combustion chamber... ill try my best to not blow this engine!! LOL i know for sure the compression must be between 170-190lbs.