I just finished the 144mm pump swap in my fx1. I got great results from the new pump but I think its time to start doing some work to the motor. I am throwing around the Idea of porting it. But I dont have a clue were to begin. I havent played around with motor tuning to much so I am looking for some advice. Do I begin by taking the cylinders off and porting those or is it another part of the motor? It is a 61x if that helps. Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FX-1 Trying to port my 61x HELP!!!!

- Thread starter gsx1r1000

- Start date

- Location

- Little Rock Arkansas

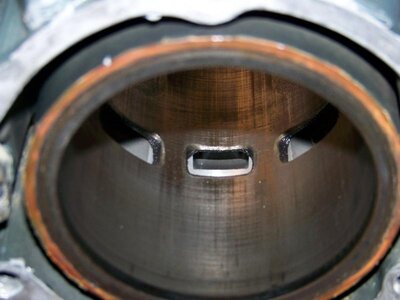

Not hard to do yourself. Widen the ex port 1 to 1.5 mm. Lots of bang right their.

Tore my motor down last weekend to fix uneven comp in cylinder 180/200. Had high spot now 185/185.

Cleaned up transfers while I was in their.

Get proper tools, under $100.

Tore my motor down last weekend to fix uneven comp in cylinder 180/200. Had high spot now 185/185.

Cleaned up transfers while I was in their.

Get proper tools, under $100.

Attachments

- Location

- Little Rock Arkansas

2strok4fun

chris w

- Location

- SoCal & Havasu

While I am a believer in "learn it and do it yourself", on this one you should prolly send it to someone trusted who can do it, or stick with the templates from sport port if you are handy. Just ripping in and even making it look good will likely net a loss in delivery and loss of a cylinder. Porting is not a "black art" it is a science, that being said, gains can be had by the do it yourselfer by matching sleeve to cylinder and cleaning up casting slag and a big one often overlooked by home porters is to insure that the xfers open exactly simultaneously.

- Location

- jacksonville florida

thats some nice looking work on that kawi cylinder. who did the work?

- Location

- Little Rock Arkansas

thats some nice looking work on that kawi cylinder. who did the work?

I thought so too, PJS.

Last edited:

- Location

- Little Rock Arkansas

Lot's of good reads and pix here on the x about home porting, search,look and read.

Freestyle port is not hard. Just need to take good measurements and do each side the same. If not the same from the factory, makem.

A H/F set will work fine for that. $10.

http://www.harborfreight.com/6-piece-technical-measuring-set-94447.html

http://www.lowes.com/pd_116217-353-...oductId=1121865&catalogId=10051&storeId=10151

Freestyle port is not hard. Just need to take good measurements and do each side the same. If not the same from the factory, makem.

A H/F set will work fine for that. $10.

http://www.harborfreight.com/6-piece-technical-measuring-set-94447.html

http://www.lowes.com/pd_116217-353-...oductId=1121865&catalogId=10051&storeId=10151

Last edited:

I've ported a number of cylinders and cases myself, but I think you get much better power by sending it to a pro. It's worth the extra money imho.

However, doing it yourself can be rewarding in itself. Grab a sport port template, a dremel, and go to town. Very nice improvement over stock.

However, doing it yourself can be rewarding in itself. Grab a sport port template, a dremel, and go to town. Very nice improvement over stock.

- Location

- Little Rock Arkansas

However, doing it yourself can be rewarding in itself. Grab a sport port template, a dremel, and go to town. Very nice improvement over stock.

Thank you for your thread on home porting. I found some help full stuff their.

We all smoke motor's time to time

Sport temp: $35 here on the X...............

Last edited:

- Location

- Little Rock Arkansas

and a big one often overlooked by home porters is to insure that the xfers open exactly simultaneously.

If you don't mind my asking, what do you do/did for a living?

I did a lot of reading b4 porting my cly. One thing that showed up a lot is "do not touch the top of any port(for bottom)".

If the home porter will follow that rule it will help to insure good gains.

Last edited:

2strok4fun

chris w

- Location

- SoCal & Havasu

If you don't mind my asking, what do you do/did for a living?

I did a lot of reading b4 porting my cly. One thing that showed up a lot is "do not touch the top of any port(for bottom)".

If the home porter will follow that rule it will help to insure good gains.

Well I dont make a living doing any engine work if that is what you are getting at

Yes, it is true about not raising ports any to maintain good bottom end delivery in almost all cases, BUT the bottom end delivery would still be improved to slightly raise 1 or 1 side of the x-fer ports to match them. This matching cant be done unless you have a right angle grinder that can get at the transfer and not bugger up the entry angle... Most of the sleeved cylinders that are common in watercraft engines are reasonably matched height wise. Any time a cylinder has been bored, the boost port needs some attention because of its steep entry angle. On edit: Of course there is nothing to match on the boost port, but to maintain original port timing the boost port need cutting after boring, that is not raising it, but raising it back to factory spec post bore, the bigger the big bore, the more the boost port need raising to get it back to spec.

Last edited:

Polish jet pilot

4aces4aces4aces4aces4aces

- Location

- Warsaw, Poland

good quote

- Location

- Little Rock Arkansas

Well I dont make a living doing any engine work if that is what you are getting at

Naw not really, it was ur writing that made me ask. Its one thing that need's improvement in my life (spelling too

Thanks for more good info.

- Location

- Little Rock Arkansas

What pump and pipe are you using?

Not sure who your asking kevbo

Last edited: