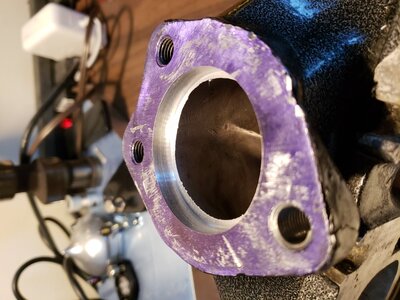

I did mine on my own when I was working in a machine shop. If you do it yourself take the time and take as many measurements as you can on making both holes line up. Using the gasket will only help you get the right diameter to match up to, sometimes those manifolds will have the outlet slightly biased in one direction or another. Mine was biased more toward the PTO side of the engine so I had to bore it more toward the Mag side to match where the headpipe was biased. When oversizing you can just skim one side of the hole while doing most of the digging on the opposite to align both parts. I think of it like this, looking at the number 8, if it were squished down mind you, it would be like looking at 2 holes slightly offside from each other. When boring larger, lightly skim the outside of the offset on both holes while taking the bulk off of the misaligned inside. This way the max o.d. encompasses both holes as a match and consumes the needed center material to give equal size holes and properly lined up with each other...