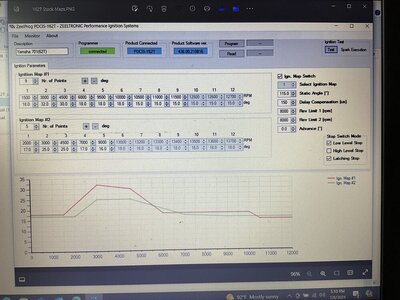

My plan, when I get around to setting up my 62t, is to program a flat curve, say 15 degrees, check with timing light at various different rpm's and adjust the delay until I get a flat curve, then re-adjust the static angle if needed so that the timing matches my programed value.

To me, ideally you want the delay setting "correct" so that things don't vary with rpm, then you want the static offset "correct" so that you get the actual curve that you program, then program your curve.

But, in reality, as long as whatever combination of settings you have works, then it doesn't actually matter, you just have to be careful using somebody else's curve if you're not sure if the delay and/or static angle are not set up the same as yours or if there is something about their combination that would cause things to be different, because you might end up effectively with a different curve and not know it.

Definitely appreciate both Wax and Jr without their efforts we'd still be talking about how far to turn the stator with an enhancer.