- Location

- Buffalo, NY

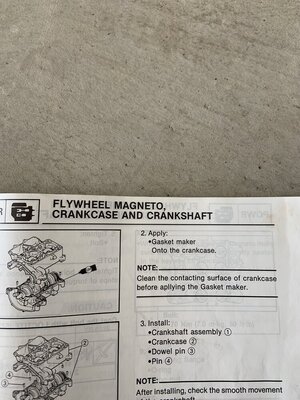

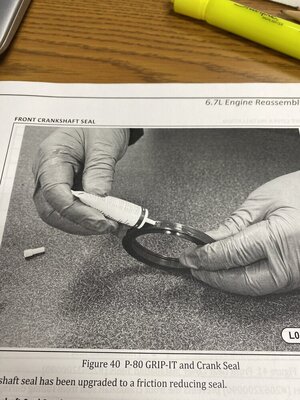

I'm rebuilding a 701 for my Superjet and I had a question about putting Threebond (Yamabond) around the crank seals. I put the Threebond between my case halves and then around the crank seals (as I usually do) and after I torqued everything down there was about a 3/4" section between one the PTO crank seal and the case where I didn't see it ooze out like it did around the rest of the mating area of the crank seal/case.

Should I split the cases to make sure that the Threebond is sealed all the way around the crank seal, or was it just maybe not put on as thick as it was in the other areas that did ooze out? Will it still seal alright? I just don't want any air leaks. Any feedback would be appreciated.

Should I split the cases to make sure that the Threebond is sealed all the way around the crank seal, or was it just maybe not put on as thick as it was in the other areas that did ooze out? Will it still seal alright? I just don't want any air leaks. Any feedback would be appreciated.

Last edited: