You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

155 Pump shoe in Superjet /Wich one

- Thread starter steve711

- Start date

- Location

- PST

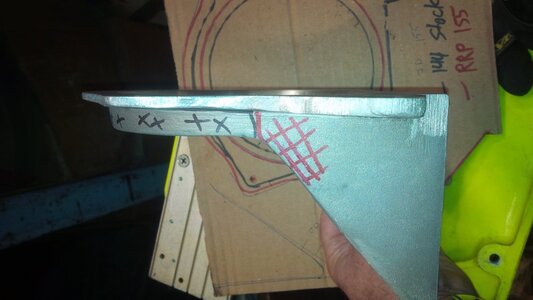

I'll take some pictures of each. The OEM 144mm flange appears to be parallel, but the JD155 and the RRP have some angle to them (narrower towards the top).

Attachments

- Location

- PST

OEM WB2

JD155

OEM RNSJ

JD155

OEM RNSJ

- Location

- Michigan

Sorry to dig up this older thread but I’m curious what your final determination of this project was? What shoe did you go with? And how did the sealing situation work out?

Also slightly off topic but for all these pump shoes, did they share the same 4 holes for screwing the shoe to the hull? Im likely going to be undertaking a project of reversing a 155mm pump and bringing it back down to a 144mm shoe and pump combo it its possible.

Also slightly off topic but for all these pump shoes, did they share the same 4 holes for screwing the shoe to the hull? Im likely going to be undertaking a project of reversing a 155mm pump and bringing it back down to a 144mm shoe and pump combo it its possible.

- Location

- Michigan

Thank you for that information, sounds like my project wont be as bad as I thought, just depends on how hacked up the pump tunnel was to get the 155 in there.My 155 rrp pump shoe used the same holes as a stock superjet pump shoe, so I think they all use the same hole locations, at least theoretically they should, I wouldn't expect any of these to just line right up without some screwing around.

- Location

- Michigan

Ahh I have heard thats an option, did you use a sealent to smooth out the transition from the lip of the pump seal to pump shoe? Or was the seal good enough without it? I finally got a picture of the hull ill be working on and it almost looks like the 155 shoe is glassed into the hull! Not sure if changing it will be worth it/ easy enough for me. I dont have any fiberglassing skills.For what it's worth, I ran a 144 pump for a while with my 155 pump shoe, the seal on the 144 pump was big enough to still seal on the 155 shoe, might be worth checking out that option.

Attachments

I used silicon on the pump seal, but that was mostly because I had a used pump seal that had already been silicon-ed and wasn't in the greatest of shape, I was throwing it together in a hurry, but it worked so I did run it that way for a little while and had no troubles.

- Location

- Michigan

Good deal, I think ill just try that. Id just get a 155 setup, but I already have the best 144 setup from my sj with a 9/15 hooker and solas mag. Plus oem 155 pump parts are pricey these days, and you need a custom driveshaft. If I ever get a larger engine than a limited 701, then ill find a 155 pump and be good to go. I appreciate your help!

- Location

- Michigan

Going to bump this again, I’m in the middle of dropping a 155 into a superjet and I cut out the entire tunnel / glassed a new one in to feed the 155 and match up to a wb2 pump shoe. Has anyone that went the 144/155 conversion shoe and left the 144 tunnel as is run into problem starving the pump or had cavitation issues? Before cutting my tunnel out I ground the pump shoe area to fit the wb2 shoe and align with the 155, and there was a good step from the 144 tunnel to the 155 shoe. I’m having a hard time envisioning the 144 tunnel being able to properly feed a 155 with such a diameter mismatch at the shoe transition.

To get the shoe lined up with the pump I literally ground the entire tunnel out (pics below.) For reference, if a person popped a mold off the outside of the pump tunnel (from inside the tray) it’d be just about perfect to line up to a wb2 shoe and 155. Just FYI.

Thanks all

To get the shoe lined up with the pump I literally ground the entire tunnel out (pics below.) For reference, if a person popped a mold off the outside of the pump tunnel (from inside the tray) it’d be just about perfect to line up to a wb2 shoe and 155. Just FYI.

Thanks all

Attachments

- Location

- Michigan

I made it, probably should have just bought a tunnel from carterb but here I am lol

It’s not finished yet, but it’s close, so please ignore all the sanding dust and rough edges

It’s not finished yet, but it’s close, so please ignore all the sanding dust and rough edges

Attachments

-

00791B46-8836-40C8-94FA-AC87BF9A5389.jpeg83.9 KB · Views: 104

00791B46-8836-40C8-94FA-AC87BF9A5389.jpeg83.9 KB · Views: 104 -

694F2B24-4E86-4943-907C-81E51F18D386.jpeg76.1 KB · Views: 103

694F2B24-4E86-4943-907C-81E51F18D386.jpeg76.1 KB · Views: 103 -

190607C3-AE02-4E36-859C-B077300F6884.jpeg95.7 KB · Views: 102

190607C3-AE02-4E36-859C-B077300F6884.jpeg95.7 KB · Views: 102 -

CF9F4673-00CD-4A44-AE38-CB2E277A4FC5.jpeg77.9 KB · Views: 96

CF9F4673-00CD-4A44-AE38-CB2E277A4FC5.jpeg77.9 KB · Views: 96 -

686B70CB-ADFF-428E-B629-C29B72215D5A.jpeg80 KB · Views: 94

686B70CB-ADFF-428E-B629-C29B72215D5A.jpeg80 KB · Views: 94 -

820608A4-2411-4061-94E9-12FB2AFD0F82.jpeg84.2 KB · Views: 92

820608A4-2411-4061-94E9-12FB2AFD0F82.jpeg84.2 KB · Views: 92 -

9C6C2515-8AEA-4A62-ABEB-2DB46A486DE0.jpeg122.1 KB · Views: 113

9C6C2515-8AEA-4A62-ABEB-2DB46A486DE0.jpeg122.1 KB · Views: 113

davidescu_radu

sea riders

- Location

- Constanta,Romania

nice work - is the best solution to fit 155 pump in sjGoing to bump this again, I’m in the middle of dropping a 155 into a superjet and I cut out the entire tunnel / glassed a new one in to feed the 155 and match up to a wb2 pump shoe. Has anyone that went the 144/155 conversion shoe and left the 144 tunnel as is run into problem starving the pump or had cavitation issues? Before cutting my tunnel out I ground the pump shoe area to fit the wb2 shoe and align with the 155, and there was a good step from the 144 tunnel to the 155 shoe. I’m having a hard time envisioning the 144 tunnel being able to properly feed a 155 with such a diameter mismatch at the shoe transition.

To get the shoe lined up with the pump I literally ground the entire tunnel out (pics below.) For reference, if a person popped a mold off the outside of the pump tunnel (from inside the tray) it’d be just about perfect to line up to a wb2 shoe and 155. Just FYI.

Thanks all

davidescu_radu

sea riders

- Location

- Constanta,Romania

I'll do a 155 pump to a rickter fs2/2010 - that has same as sj 144 tunnel - only maybe a larger intake area - problem is that the rrp pumpshue(i've bought) has a bad angle - the best 155 pumpshue is from B2 (factory as usual) - and someone should make a aluminium copy of it - maybe i'll try

davidescu_radu

sea riders

- Location

- Constanta,Romania

- Location

- Michigan

Looks good! I like that setup

davidescu_radu

sea riders

- Location

- Constanta,Romania

I'll produce more this winter - same yamaha oem style - no rubber ring

All summer i have tested one on my rickter fs2 5mm stroker - after having to work hard to enlarge the intake duct(was design for 144) to fit and align the pump/pump shue and engine ( because with 155 pump - you need a 10 mm longer shaft for full splines engage, also pump is larger in diameter and then your shaft on pump side will be lower than 144 so will enter the hull on more angle - so you will need to lift a bit the front of engine to be all aligned) - so after all this trouble - 155 with right impeller is super

You have to use sealant between wear ring and my pumpshue - and after final alignment and sealed - when you want to work on pump/impeller leave the wear ring in place and all will be easy to reinstall - so you need to have the blaster 2 style 8mm long bolts and blaster 2 wear ring with treads on it for long bolts

All summer i have tested one on my rickter fs2 5mm stroker - after having to work hard to enlarge the intake duct(was design for 144) to fit and align the pump/pump shue and engine ( because with 155 pump - you need a 10 mm longer shaft for full splines engage, also pump is larger in diameter and then your shaft on pump side will be lower than 144 so will enter the hull on more angle - so you will need to lift a bit the front of engine to be all aligned) - so after all this trouble - 155 with right impeller is super

You have to use sealant between wear ring and my pumpshue - and after final alignment and sealed - when you want to work on pump/impeller leave the wear ring in place and all will be easy to reinstall - so you need to have the blaster 2 style 8mm long bolts and blaster 2 wear ring with treads on it for long bolts

davidescu_radu

sea riders

- Location

- Constanta,Romania

this set up works perfect - if u work for alignment when glue the pumpshue

- Location

- Sacramento

I used a worx 155 in my SN build. Fit great and easy to install, definitely felt a lot smoother and more bottom end after swapping stock prop with hooker 9/15, cleaning and resealing pump, wear ring. Soo much better, I believe the worx is one of the only shoes that taps and threads the mounting holes as well which I know isn’t a big deal, but saved some time with install.