I have a 2001 GP800R that I recently finished a rebuild on and I’m now facing a issue regarding RPM’s in the water.

Carbs are rebuilt and engine was completely taken apart and rebuilt from the ground up with new gaskets, plugs, throttle cable, etc.

Everything seems fine on the ski when I’m testing it with the garden hose attached and am getting 8,000 RPM when I’m at full throttle out of the water. However, when I drop the ski in the water the ski refuses to go above 3,000 RPM no matter what I do. There are no idle or cranking issues with it as well and fires up instantly every time.

Anyone got any ideas on where to start looking to fix this issue?

Side Note:

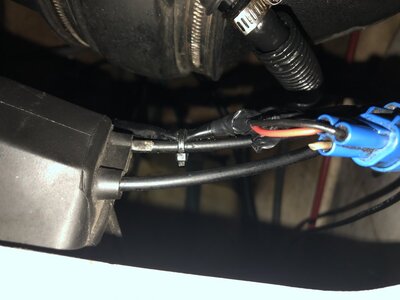

The person I bought it from had some shop jerry rig the fuel cock system as well for whatever reason and has wires spliced together in order to bypass the fuel sensor.

When I reconnect the wires properly the fuel sensor cause a warning light to flash on the dash.

My best guess is it has something to do with this whacked out fix but, I wanted to get a second opinion before I started throwing more parts at it.

Carbs are rebuilt and engine was completely taken apart and rebuilt from the ground up with new gaskets, plugs, throttle cable, etc.

Everything seems fine on the ski when I’m testing it with the garden hose attached and am getting 8,000 RPM when I’m at full throttle out of the water. However, when I drop the ski in the water the ski refuses to go above 3,000 RPM no matter what I do. There are no idle or cranking issues with it as well and fires up instantly every time.

Anyone got any ideas on where to start looking to fix this issue?

Side Note:

The person I bought it from had some shop jerry rig the fuel cock system as well for whatever reason and has wires spliced together in order to bypass the fuel sensor.

When I reconnect the wires properly the fuel sensor cause a warning light to flash on the dash.

My best guess is it has something to do with this whacked out fix but, I wanted to get a second opinion before I started throwing more parts at it.