Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

Loosen motor mounts, push out from center. Also you may need to loosen bed plates and push in/out as well.

.

.

Did you silicone or modify a coupler/oring for the inside of the tnt manifold?Engine Install:

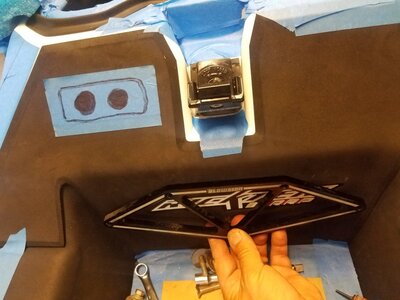

Installed the Engine then put in the pipe, gastank and waterbox to see hw it all fits. The first thing we noticed is the Freeriderz Airbox that I love so much just doesn't fit in this hull. I guess you can make it fit but you loose access to the throttle cable and it makes the engine compartment way too crowded. I am going to use regular Aftermarket Flame arrestors and put the Freeriderz airbox up for sale. OK I've barely slept in days but the adrenaline is now starting to kicki in. I want this baby on the water. View attachment 377235

I haven't added one, do you think that's required?Did you silicone or modify a coupler/oring for the inside of the tnt manifold?