- Location

- new zealand

This is my js300. You might have seen it in my previous posts. It had always had one of those rock and roll type motors that when running look like they are ready to jump off the motor mounts. The bad vibrations were due mostly to the little end of the rod being a bit worn out and having some freeplay in it.

Recently the freeplay got worse resulting in the piston slapping the cases each time it came down and I rode it untill it was unrideable due to the motor cutting out over half throttle.

I wasnt too upset because i had known that the motor was due for a rebuild for some time but i was gutted to find that the vibration from the piston hitting the cases had cracked the casting on the barrel making air/oil bubbles come out from around the bottom of the transfer ports. I liked that barrel cause it had a really nice port job and where it had cracked it cant be welded. Ill get some pictures of the cracks soon.

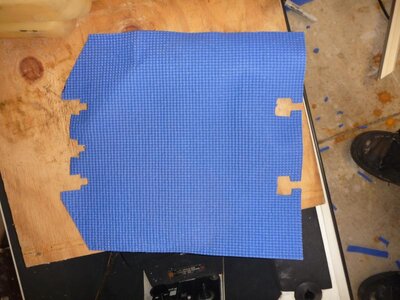

So I began the rebuild I want to make a nice job of it cause this was my first ever jetski and i have heaps of memories attached to it.

Recently the freeplay got worse resulting in the piston slapping the cases each time it came down and I rode it untill it was unrideable due to the motor cutting out over half throttle.

I wasnt too upset because i had known that the motor was due for a rebuild for some time but i was gutted to find that the vibration from the piston hitting the cases had cracked the casting on the barrel making air/oil bubbles come out from around the bottom of the transfer ports. I liked that barrel cause it had a really nice port job and where it had cracked it cant be welded. Ill get some pictures of the cracks soon.

So I began the rebuild I want to make a nice job of it cause this was my first ever jetski and i have heaps of memories attached to it.