- Location

- Mechanicsburg, PA

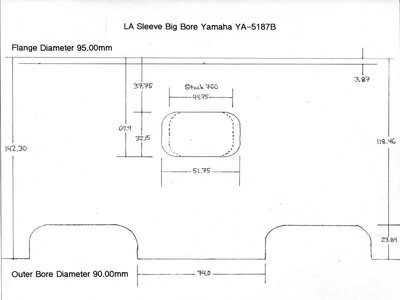

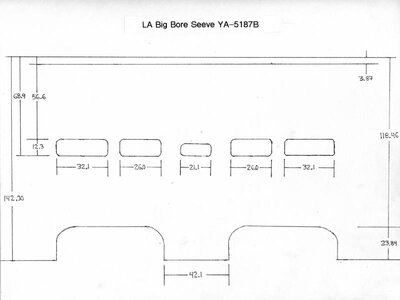

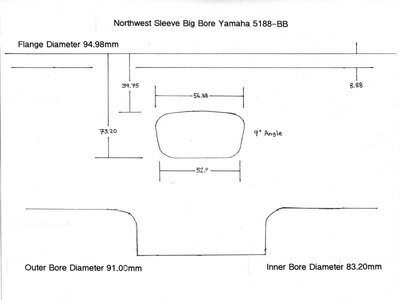

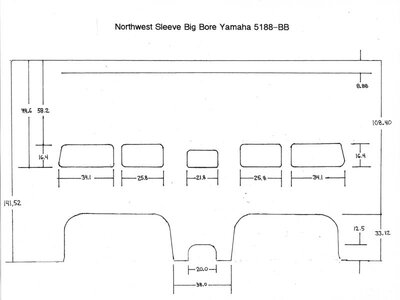

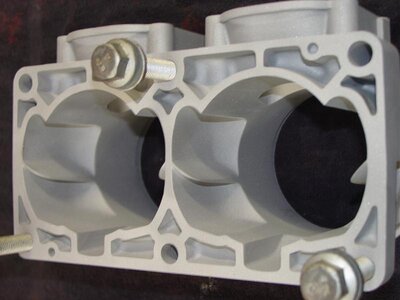

Does anybody know if there is a difference in port mapping between the LA Sleeve and Northwest Sleeve 61X big bore sleeves? I think I've read that the NW sleeves leave the option open for doing a stroker later becuase of lower port heights.....correct?

What's required, besides a stroker crank, to build a standard big bore 61X into a big bore stroker (4 or 5 mil)?

What's required, besides a stroker crank, to build a standard big bore 61X into a big bore stroker (4 or 5 mil)?