- Location

- Spring Lake, MI

He said the original case hardening should be fine for boring the hole from 25mm to 26mm but will check when complete. te4250, sent you a pm

How do you measure the return and fuel psi?I was able to get the ski out to the lake this week for the first water test. No other changes to the ski from last year other than adding 15 pounds of reinforcing fiberglass, switching to a kart tank, and a bump in battery size from a btz9 to btz12. Took it easy and checked over for leaks. Engine felt responsive and acted similar to how it did last year. It ran quite rich but didn't foul plugs after burning a couple gallons. For carbs I'm using silver mikuni sbn44s with drilled returns and running a 70 jet. Last year that got me in the 1.5 psi idle, 6psi wot fuel pressure. I figured that should be rechecked and planned on bumping the jet up a bit due to the stroker crank. Turns out there was some crud in the return jet. I should've checked pressure before cleaning it. I tested on the stand with a 70 and 90. the 90 should work fine, it gets me close to what it was last year. Sounds much more crisp now that it isn't clogged. Also found one of the low speed screws was a half turn different from the other. Will update after more testing is done.

What tool did you use to cut your domes? I’ve got to do the exact same thing. Need to cut down 0.131” if using the stock 0.020” base gasket for my 5mm stroker to get 0.045” squish. Looking for bottom end. Have a 0.080” spacer plate and different sized base gaskets I could use as well. Here’s my port timings with different base gasket thicknesses as measured. Problem is I don’t know what would work best on a stroker.Motor is put together and running. Initial cold and oiled compression was 180 stator/190 pto psi. After first start to blow out the excess oil was 175/180. Keep in mind I'm using the same used pistons and rings as before, probably 200+ gallons but still looking good. I want to dial in the tune and hopefully get one more season on it before boring it out. It does have new conrod bearings, pin, and circlips. Will be a few weeks before it hits water. Very happy with how little vibration there is. Using OEM couch mounts.

View attachment 423486

View attachment 423487

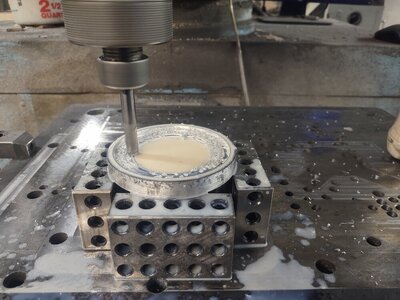

Ok awesome. Ya my father in-law is a machinist but I don’t believe they have a CNC machine. May have to get them machines somewheres else. My domes are ADA 35cc domes for a 701. I figured if everything was taken down exactly 0.131” then I’d keep the same volume and have the proper squish. Do you have your CAD file that you could share by any chance?I used my cnc machine at work to cut the domes. I'm able to model the domes in cad first to verify the volume before actually cutting. Having a couple sets of 701 domes gives you extra meat to cut away from. I'm not an expert, but I prefer to keep the port timings as close to stock as possible to keep the powerband in the same location. that means 180 degrees of exhaust and 120 degrees of transfer. You'll make more power with more exhaust duration but will take ignition timing, carburation, and pump work to get it to the high rpm quick.

You don't need a cnc mill to cut the domes. You can do it on a manual lathe or milling machine just as easily. Easiest would be on the lathe. Chuck the dome at the shoulder where the seal goes into the around the plug threads, dial the desired angle into the cross slide. With a facing tool, touch off, dial in your depth indicator and pull the tool towards you with the cross slide.

You're right I wasn't talking about the actual dome part. For that you can use a ball turning attachment in the cross slide. I've seen a guy on youtube modify a boring bar setup for a mill to do ball ends on his mini lathe. I have not tried it but did start a new job this past November operating a manual lathe and milling machine and absolutely love it.You descirbed how to do the squish band, which is pretty easy, but did not mention how to do the dome, which is trickier.

Possible with a manual lathe, but by far the dome is the tricky part.