- Location

- Midwest

Hello all,

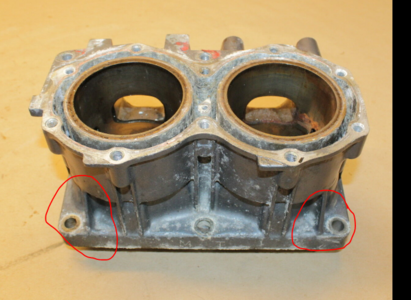

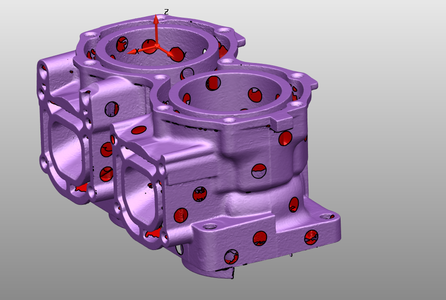

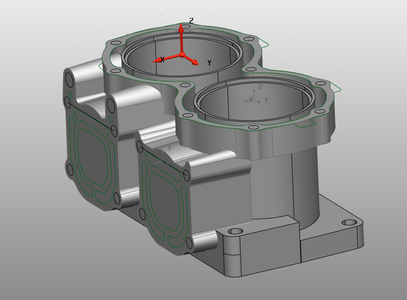

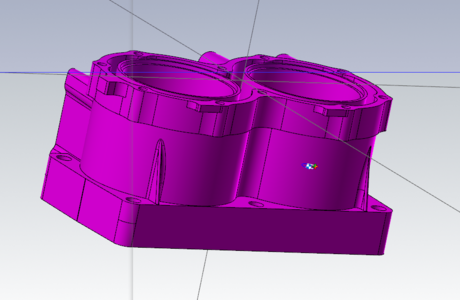

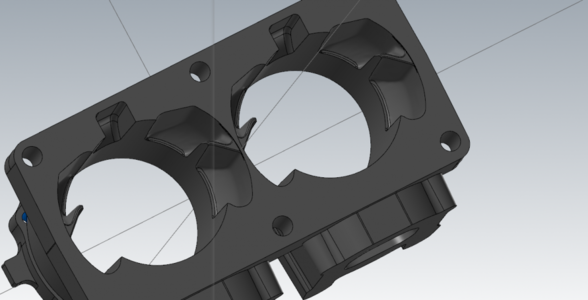

I am new to yamaha, i have multiple kawis including a 440, 550sx, 650sx, and sxr800. I have convinced the company i work for to 3d scan and machine from billet a jet ski engine (castings only) for a trade show this september. I chose the 701 because i want a super jet and never really got around to buying one, either way the 701 has the best current aftermarket and People seem to rave about ite. I did just a touch of research and found that the 62t cases coupled with the 61x jug seems to be the most desired for the stock 701cc setup in a superjet. So i ordered 62t cases and a 61x jug and head from ebay. Today we got the jug in and scanned it to an STL file. We are currently working on modeling the solid and i was wondering if i selected the best castings and what changes you may recommend to the castings i have selected. Thanks in advance for any info.

I am new to yamaha, i have multiple kawis including a 440, 550sx, 650sx, and sxr800. I have convinced the company i work for to 3d scan and machine from billet a jet ski engine (castings only) for a trade show this september. I chose the 701 because i want a super jet and never really got around to buying one, either way the 701 has the best current aftermarket and People seem to rave about ite. I did just a touch of research and found that the 62t cases coupled with the 61x jug seems to be the most desired for the stock 701cc setup in a superjet. So i ordered 62t cases and a 61x jug and head from ebay. Today we got the jug in and scanned it to an STL file. We are currently working on modeling the solid and i was wondering if i selected the best castings and what changes you may recommend to the castings i have selected. Thanks in advance for any info.