- Location

- Stony Plain, Alberta, Canada

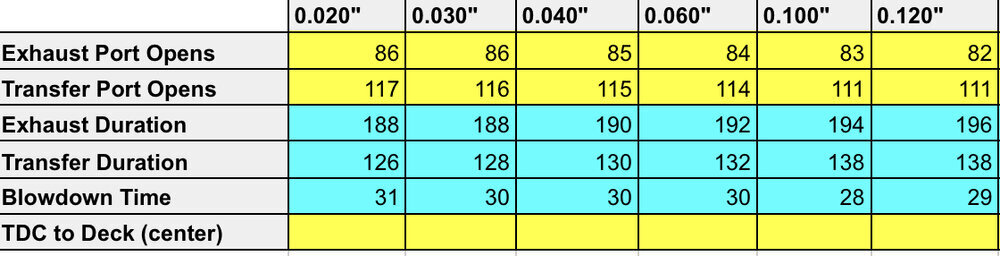

I have a 96 Superjet and upon putting in new crank seals and top end, I realized the ski is a 5mm stroker (73 mm stroke) with 62T cylinders and trenched cases. I had just ported my exhaust and intake ports from Yamanubes template. Had a protec head on which had 150-160 psi. Had to take 0.0125” out between the head and cylinder as there was some warpage. When at BDC the edge of the piston is pretty much perfectly at the bottom of the exhaust port. The top of the piston protrudes 0.263” above the cylinder deck when at TDC. I was planning on putting a girdled ADA head on with 35cc domes for approx 185 psi, but I would now require me to add a 0.080” spacer plate and 0.040” base gasket, which would raise my porting by 0.120” (3.048mm) to get the proper squish (0.045”). Now would raising the porting just over 3mm really badly affect my bottom end? Also my timing would remain the same as TDC would still be the same correct? I’m looking for primarily freestyle riding.

My other option is to just machine the protec head for the proper squish which should leave my porting but then I don’t have the added insurance of the girdled head.

Or if possible get the domes machines 0.120” up but that seems like a lot!

Picture of piston at TDC. Keep in mind this is my first time working on a 2 stroke so please bear with me.

My other option is to just machine the protec head for the proper squish which should leave my porting but then I don’t have the added insurance of the girdled head.

Or if possible get the domes machines 0.120” up but that seems like a lot!

Picture of piston at TDC. Keep in mind this is my first time working on a 2 stroke so please bear with me.