Hey kids I've got a 701 61x stock stroke stock bore 81 mm to achive port timing of roughly 125 degrees what are the mesurements in mm the top of transfers and exhaust port from top of cylinder need to be I'm getting mixxed numbers down in aus it's running a base gasket as well roughly .5 mm it's stock as well . Also on a free ride potted motor including case porting the same as above what kind of comp should it be getting with an Ada head and 33cc domes ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

701 porting

- Thread starter Cranes

- Start date

waxhead

wannabe backflipper

- Location

- gold coast

http://x-h2o.com/showthread.php?t=21863&highlight=port+timing+freestyle

Here is a link that may be useful for you

You may find post 35-36 interesting

Here is a link that may be useful for you

You may find post 35-36 interesting

Ok thanks wax I've currently got a cylinder ported from a guy on this site the transfers are 52.2mm from top of cylinder and exhaust is 34.5 mm what port duration in degrees does this give me on my motor stock stroke 81mm piston .5 mm base gasket I've been told it's awesome for free style ? A few answers please guys wax is help full but a bit conflicting at the moment I want American addvice ha ha the cylinder is 119 mm tall has not been milled . Yet

Last edited:

SUPERTUNE

Race Gas Rules

- Location

- Clearwater Fl.

From the looks of the #'s you posted...fairly aggressive, almost super stock porting.

Don't overprop it, run a programmable ignition, or race gas compression ratio, could be a little flat off the bottom if you don't set it up for this type of porting.

Don't overprop it, run a programmable ignition, or race gas compression ratio, could be a little flat off the bottom if you don't set it up for this type of porting.

SUPERTUNE

Race Gas Rules

- Location

- Clearwater Fl.

Yes, I see it all the time. I'm always the bearer of bad news when I see some customer engine setups... But the good news is, for $$ we can make them very happy again!

Check with Craig soon at AJSP there, as we just sent him some SS 865 engines and top ends for the stock stroke packages.

Check with Craig soon at AJSP there, as we just sent him some SS 865 engines and top ends for the stock stroke packages.

Thanks mate your motors are very high on our shopping list I talk to Craig way to much ha ha I also have another motor issue that we are trying to sort out at the moment it's a brand new billet dasa 5mm 85mm piston power valve motor the motor has some weird mesurments we are trying to sort out hope fully dasa will get back to Craig soon so I'll leave it at that now till I here but if any one has built a dasa 5mm 85mm piston motor motor I would love to talk to u about deck heights and so on we have 2 brand new rickters with brand new every thing that run like crap the stroker is worse then the 701 for bottom end power

The engine builder had it set at 150 tp 155 psi comp with 1.2 squish on pump gas it goes like a golf cart it's for a rickter surf boat it sounds like we didn't get what we wanted !

Its over propped. Learn how to bend them.

the best way for a imediate answer on this question would be to put up both exhaust and transfer measurments in millimeters and ask those in the know as to what they mean in real figures crankshaft rotation. My understanding of this so far is there is a discrepency as to what measurment in millimeters is crankshaft rotation

so the more guys in the know that can comment as to what these measurments mean in crankshaft degrees the better

i am sitting on the fence until the jury is out as at the moment i know everyone involved but would be good to see a end to the dispute as i hate seeing guys burnt in this industrie as its to small to be driving people away with bad workmanship or poor expectations

so the more guys in the know that can comment as to what these measurments mean in crankshaft degrees the better

i am sitting on the fence until the jury is out as at the moment i know everyone involved but would be good to see a end to the dispute as i hate seeing guys burnt in this industrie as its to small to be driving people away with bad workmanship or poor expectations

SUPERTUNE

Race Gas Rules

- Location

- Clearwater Fl.

I'll run some #'s when I get back to the shop...

All you need to do is go to a speed shop or go online and buy a nice aluminum degree wheel, make an adapter for the crank bolt to hold it up tight, make up a piston stop to use to indicate the pointer, then you can read your own port mapping in degrees and then you will learn like I did when I started doing this 25 years ago...

C

All you need to do is go to a speed shop or go online and buy a nice aluminum degree wheel, make an adapter for the crank bolt to hold it up tight, make up a piston stop to use to indicate the pointer, then you can read your own port mapping in degrees and then you will learn like I did when I started doing this 25 years ago...

C

waxhead

wannabe backflipper

- Location

- gold coast

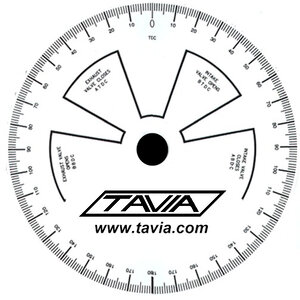

I like this software here for working out timing

I use a degree wheel when I am assembling the engine but to get the ports close i use this

It also works well for working out ignition settings using dial indicator down the bore

http://john.rushworth.com/Pics/Piston/

I use a degree wheel when I am assembling the engine but to get the ports close i use this

It also works well for working out ignition settings using dial indicator down the bore

http://john.rushworth.com/Pics/Piston/

- Location

- Sydney Australia

OK, to add a little more clarity to this thread it is my motor. It was built by Steve Cunningham (aka Carbon Blaster aka InfusionT). The purpose of this thread is that I have a motor that does not run very well (no throttle response). I've had another engine builder tell me that the porting is far too aggressive for what I want a motor for (it is going in a rickter for surf riding), As you can imagine, I am in the middle of one word against another. It is petty that it has come to this but it has been a long journey and I need an impartial opinion. The numbers are as Cranes has said. Another thing is that Steve built the motor with 35cc domes which produced a little over 150psi comp. (which he adamantly claimed was enough) I changed the domes to 33's which boosted the comp to just under 170psi. The comp just seems too low? Is there anything in the numbers listed that would explain the low comp? Yes, we even bought a new comp gauge just to check....

Transfer is 52.2 mm exhaust is 34.5mm how does that stack up

I built a small program for calculating timing a while ago...

and get this kind of figures for your measurements.

Transfert open(t0) 52,2 Open Timing 115 Duration 130

Exhaust open (h0) 34,5 Open Timing 83 Duration 194

BlowDown 32

It might be off by 1deg based on how you measure it so don't take my numbers for granted... but should not be too far from the real figures.

Of course, it makes the assumptions that base gasket, cylinder height etc... are standard.

Would love to hear from a pro (chuck) as to the values he finds so I can adjust my prog eventually...

hope this helps.

masterblaster

X-H2

3rid,id like to have some software like that.I used a degree wheel on a cylinder recently and came up with the same exh duration but a different transfer duration than a engine builder that had degree wheeled it. Do you guys use a feeler gauge or just look for the first bit of light coming through the port? I was off 2 degrees from what it was stated to be.

it is 39.60 exh

59.10 transfer

it is 39.60 exh

59.10 transfer

Cannibal

Tasty Human

- Location

- Summit Lake, WA

I have printed this out and resized it to fit on a cd to bolt on the crank snout, and bolted a pointer to the case cover bolts.

Awesome! I was just about to order one from Car Quest at the tune of $35. Muchas Gracias my friend.

Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

OK, to add a little more clarity to this thread it is my motor. It was built by Steve Cunningham (aka Carbon Blaster aka InfusionT). The purpose of this thread is that I have a motor that does not run very well (no throttle response). I've had another engine builder tell me that the porting is far too aggressive for what I want a motor for (it is going in a rickter for surf riding), As you can imagine, I am in the middle of one word against another. It is petty that it has come to this but it has been a long journey and I need an impartial opinion. The numbers are as Cranes has said. Another thing is that Steve built the motor with 35cc domes which produced a little over 150psi comp. (which he adamantly claimed was enough) I changed the domes to 33's which boosted the comp to just under 170psi. The comp just seems too low? Is there anything in the numbers listed that would explain the low comp? Yes, we even bought a new comp gauge just to check....

Just because you get to 170 lbs of compression does not necessarily mean that is still pump gas safe. Anytime you port a motor, if you raise the exhaust ports you will be lowering your compression. Depending on your setup, you may end up needing race gas @ 170-180 lbs compression. There is much more to it. Look at some of the tripple cylinder motors compressions. They run much lower. It is not always about the compression number you get.

Supertune can explain this much better. If your wanting an outside opinion, give him a call or shoot him a PM. Chucky is about one of the 5 or so people on this site who really knows what he is talking about (Professional).