- Location

- Huntsville, AL

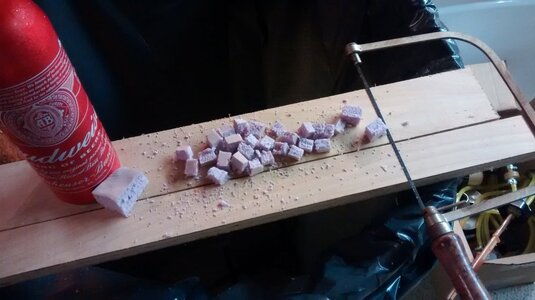

I bought the ski with a diy fiber class kick plate on the tray and some nice rails. I rode it for the summer like that and broke/cracked the kick plate. When replacing the kick plate and I find this: see pictures.

It is mushy where I slid that screw driver down in there. If you press hard on one side water seeps out the other hole... Overall, the tray is still ridged and hard everywhere else.

It is mushy where I slid that screw driver down in there. If you press hard on one side water seeps out the other hole... Overall, the tray is still ridged and hard everywhere else.

Attachments

-

IMG_20151018_173230862.jpg94.4 KB · Views: 94

IMG_20151018_173230862.jpg94.4 KB · Views: 94 -

IMG_20151010_141345711.jpg102.3 KB · Views: 93

IMG_20151010_141345711.jpg102.3 KB · Views: 93 -

IMG_20151012_185557947.jpg76.3 KB · Views: 92

IMG_20151012_185557947.jpg76.3 KB · Views: 92 -

IMG_20151012_185613798.jpg71.7 KB · Views: 88

IMG_20151012_185613798.jpg71.7 KB · Views: 88 -

IMG_20151012_190409443.jpg76.3 KB · Views: 88

IMG_20151012_190409443.jpg76.3 KB · Views: 88 -

IMG_20151012_190423148.jpg77.1 KB · Views: 88

IMG_20151012_190423148.jpg77.1 KB · Views: 88 -

IMG_20151018_173239490.jpg95.8 KB · Views: 89

IMG_20151018_173239490.jpg95.8 KB · Views: 89 -

IMG_20151018_173226751.jpg112.3 KB · Views: 92

IMG_20151018_173226751.jpg112.3 KB · Views: 92

Last edited: