AZRIDER

stupid desert

- Location

- TUCSON ARIZONA

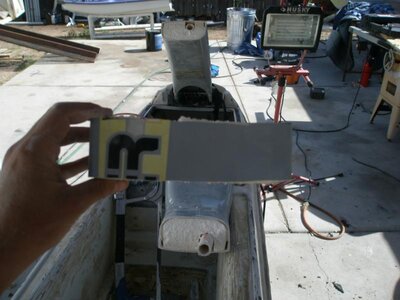

I have a 1990 superjet squarenose with a 701 61x 62e.

has blowsion handlepole spring (stock handle pole length)

limiting rope and hood straps larger bow eyes worx intake grate

It still has the ride plate i got it with(Dont think its stock says "mariner" but i have noidea

0 degree bars

I got a new "B" pipe, a billet airbox, new head w/ 82 mm 37 cc domes

This morning i began by cleaning out the hull

I then pulled apart the exhaust and motor; Inside of motor was really dirty which made me decide to pull apart the jugs to take a better look

has blowsion handlepole spring (stock handle pole length)

limiting rope and hood straps larger bow eyes worx intake grate

It still has the ride plate i got it with(Dont think its stock says "mariner" but i have noidea

0 degree bars

I got a new "B" pipe, a billet airbox, new head w/ 82 mm 37 cc domes

This morning i began by cleaning out the hull

I then pulled apart the exhaust and motor; Inside of motor was really dirty which made me decide to pull apart the jugs to take a better look

Last edited: