I suppose you have to cut a flywheel cover to keep bendix in place , and how you do with timing lamp , I had never use it thanks your help

Welcome. And yes you’ll have to cut a cover....

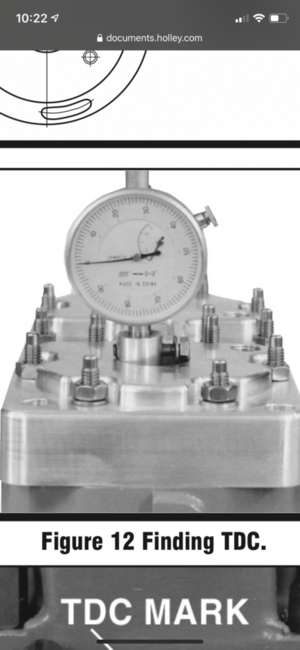

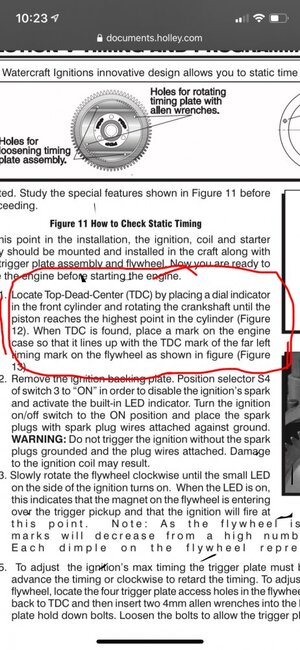

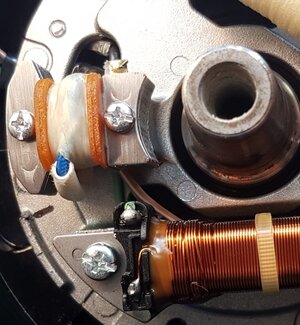

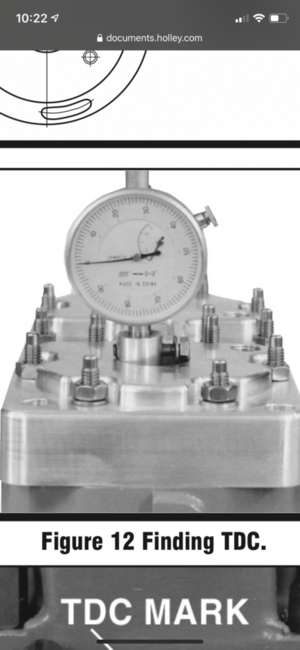

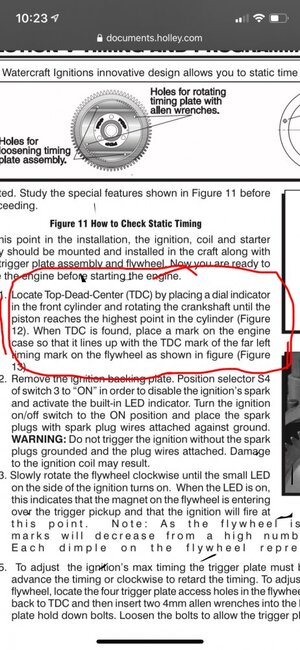

So you’ll have to decide which method your going to use to find TDC and index mark your flywheels TDC position. 2 methods to choose from, one is with a dial indicator and the other is with a degree wheel and pointer and positive position stop.... the dial indicator method requires less purchases I guess so we’ll go over that one.... you can buy it off eBay fairly cheap....pic of mine attached...

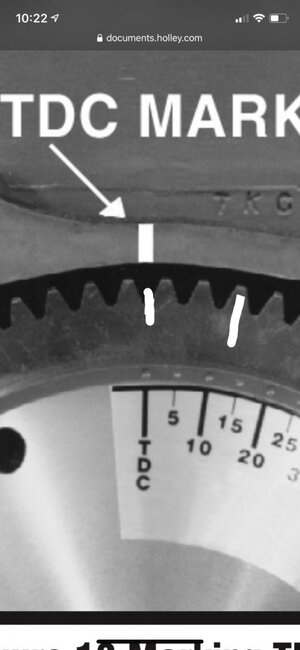

MSD instructions attached to find TDC with a dial....

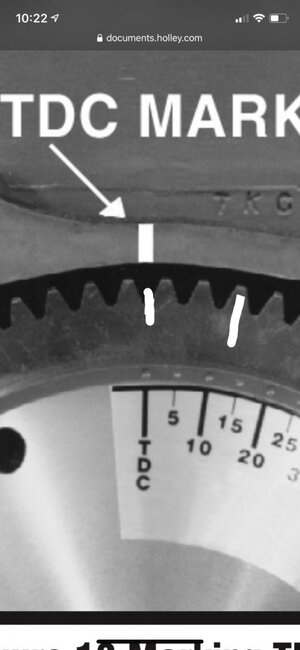

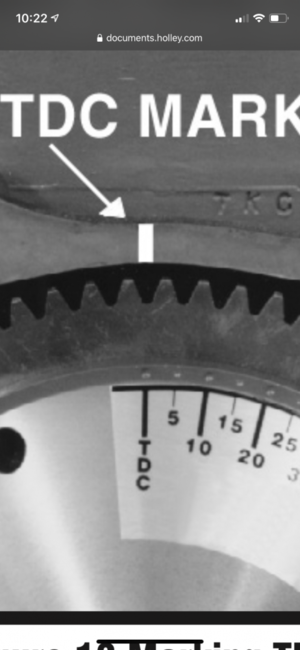

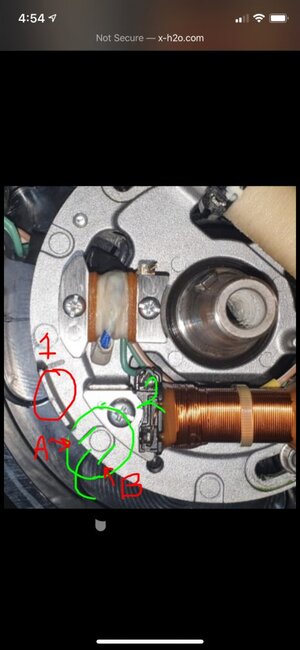

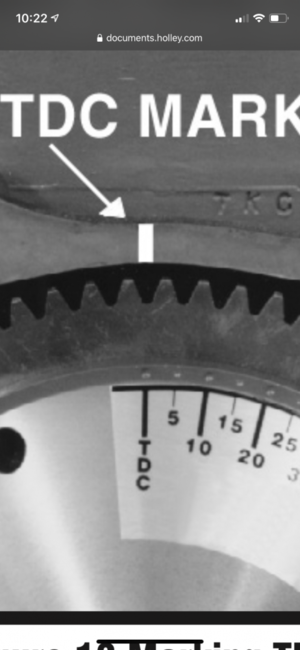

See photo’s... once you’ve found TDC and marked your case tdc and flywheel tdc, see pic,

count to the right about 2.5 flywheel teeth and put a longer line, see pic....

That’s iabout 12 deg..... see pic,

each valley of flywheel tooth to the next valley of the next tooth is about 5 deg, see pic

So you can count out timing even over to 23 deg worth and put a mark....

If your using an msd enhancer the cranking timing should be about 12 deg and total running timing about 23 deg.....

As the engine is cranked the timing marks on flywheel will walk to the left if your facing the engine, and when running And brapping will go even further left as it advances and when rpm slows down it will retard and go right..

Since your flywheel has no marks you may want to paint Mark the tip of the tooth’s face instead of the valley so it’s closer to the case when your trying to view it with engine cranking... may be easier to see...

So once you’ve found tdc and made your marks... install your cut cover and remove your spark plugs and put them into the plug boots and ground the plugs against the engine case. Hook up your timing light to a battery and clamp the inductive clamp over the front cylinders plug wire... while standing and looking at the face of flywheel crank the engine over and shin the flashing strobe light at the spinning flywheel and try to read if the 12 deg Mark you made is aligning with the tdc mark you made.... if yes, start the engine and rev to 3 or 4,000 rpm and see if the Mark you made at 23 aligns with the TDC mark you made.....

Note: you may see a lot of bouncing in the timing when it’s running, in other words the flywheel Mark is dancing around retarding and advancing randomly... its normal anomaly... noise....

If you hit 12 deg cranking with an msd enhancer id say your good.... checking it running isn’t that much more work though and is important...

Critical to Accurately find tdc

I can explain the other tdc method if needed..