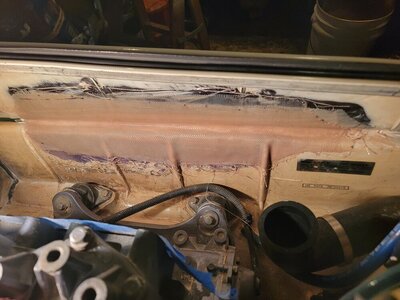

I'd pull the engine, tank, and waterbox. Then you can easily lay the hull on its side and work on it. I'd grind out the old repair, fill in the bond line on the inside and add 3 layers of 8oz cloth over the entire area top and bottom to reinforce everything. Once that's done you can grind the outside smooth and fill it in with some fairing filler.. since you've never done glasss work before, consider doing some research on the products you'll want to use as well as watch several videos from YouTube.. glass work isn't too difficult but there is a process to do quality work and you can quickly make a big mess that will waste lots of time and materials if not followed or shortcutted. Or using the wrong material for the job.. I taught myself how to do glass work in that same manner. There are some good build threads on this forum that have lots of useful information on doing glass work. Surface prep is half the work making sure the surface you're glassing is sanded and clean of dirt and grease.