- Location

- New Mexico

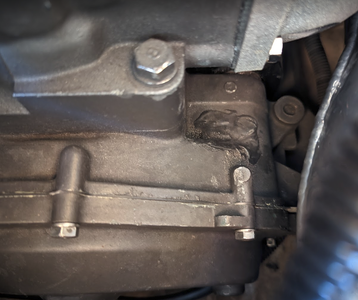

Got my B Pipe installed into my SN and the fit is still really tight against the sidewall. The chamber appears to even be absorbing some vibration from the engine which I would assume to be bad. I took a mallet to it but it really doesn't want to bend along the weld. I am a little nervous about trying to hit it right on the weld. Any tips for getting this puppy to fit better?

The first 8 inches or so right along the top weld appears to be my main pain point.

The first 8 inches or so right along the top weld appears to be my main pain point.