it’s called the power factor pipe. That lay down pipe has the same tune spec as the FPP Type 9 dry race pipe. If FPP or someone else was to redo the B pipe to a bigger spec you would lose the feel it has today.

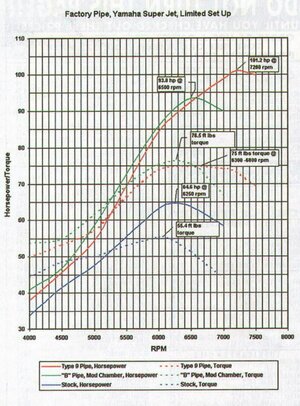

this dyno chart was made on a competitors motor back in 02’. 2002 IJSBA limited ski rules build. (no porting)

61x cylinder@82mm, 62t cases, either 48 full specs or novis, can’t remember exactly what he had at that time, MSD enhancer, Billet head with domes. You can clearly see why the average person prefers the B pipe type power

(torque) and why other newer dry pipes kill it with HP.