- Location

- San Diego

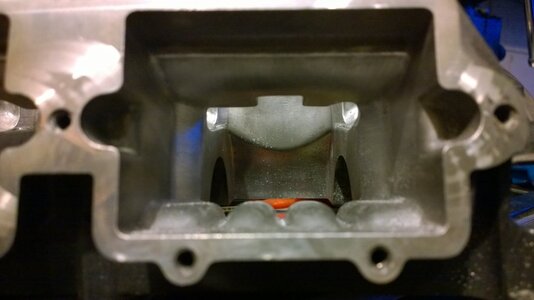

Well I bought my first roundnose superjet last year in pieces. Always rode 650s and decided to step it up finally. Since the lowest priced SJ I could find was over $4k I decided to jump on this 2001 that was in pieces for $1000. It was a freshwater ski and I saw it as a chance to build a ski I knew wasn't in salt or abused. Came with a perfectly clean, uncut and already sanded hull and hood, stock handlepole, 62t/62t motor, all electronics minus battery, pump, midshaft, two carbs, intake manifold, exhaust minus waterbox and tubing, and some other small stuff.

So far I've bought:

Footholds

Rad Dudes lowered stainless pole mount

Blowsion steering system

Blowsion Bars

New On/Off Switch

New Monkey Grip motor mounts

Solas scoop grate

82mm Pro x piston kit (getting cylinder bored +1mm)

Fuel/Cooling lines

Fuel Tank

Still need to buy:

Waterbox

Ride plate

Throttle and cable

Steering cable

Chinpad

I have the fuel selector petcock but it's missing the knob

Now that I've given you guys the story here's a few questions:

1) The ski came with a 62t cylinder, I know the preferred is the 61x, but it came with the 62t and I couldn't find a 61 anywhere for less than 400. I get the cylinder back from boring tomorrow. 1mm over. I noticed the exhaust that came with the ski says 61x, will this fit on my 62t?

2) I also noticed the midshaft says 61x on it too, will this work? I'll post a pic of it.

3) I was able to get the pistons off the rods earlier with a C-clamp, socket and wood. The crank is still in great condition and spins perfectly. Anything I should do before I put the top end back on? Like preventative? Other than cleaning it.

All info is greatly appreciated. I know a decent amount about mechanics but I'm no pro and always looking to learn. Again, this is my first superjet and I'm looking forward to getting out in the water here in San Diego

So far I've bought:

Footholds

Rad Dudes lowered stainless pole mount

Blowsion steering system

Blowsion Bars

New On/Off Switch

New Monkey Grip motor mounts

Solas scoop grate

82mm Pro x piston kit (getting cylinder bored +1mm)

Fuel/Cooling lines

Fuel Tank

Still need to buy:

Waterbox

Ride plate

Throttle and cable

Steering cable

Chinpad

I have the fuel selector petcock but it's missing the knob

Now that I've given you guys the story here's a few questions:

1) The ski came with a 62t cylinder, I know the preferred is the 61x, but it came with the 62t and I couldn't find a 61 anywhere for less than 400. I get the cylinder back from boring tomorrow. 1mm over. I noticed the exhaust that came with the ski says 61x, will this fit on my 62t?

2) I also noticed the midshaft says 61x on it too, will this work? I'll post a pic of it.

3) I was able to get the pistons off the rods earlier with a C-clamp, socket and wood. The crank is still in great condition and spins perfectly. Anything I should do before I put the top end back on? Like preventative? Other than cleaning it.

All info is greatly appreciated. I know a decent amount about mechanics but I'm no pro and always looking to learn. Again, this is my first superjet and I'm looking forward to getting out in the water here in San Diego