- Location

- flroida

2008 Yamaha Waverunner deluxe. Here’s what I’ve done to it:

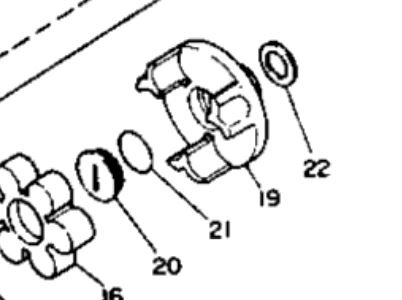

New Yamaha wear ring

New solas 14/20 dynafly (it is TIGHT; within spec for clearance on wear ring)

New solas intake grate

Filled the pump shoe with flex seal

Resealed ride plate, intake, etc

New fuel pump

New fuel injectors

New spark plugs

now the issue. When I pin this thing, it will almost immediately hit the rev limiter. From stop it will go for 1 second without it , but if I go WOT it will hit that rev limiter pretty much no matter how fast I’m going. Trim makes little difference. It seems like anything above 75 throttle it hits that limiter. I can do 45mph on it, and with the 75 throttle it gets good traction from what I can tell. I’m at a loss here! Where else can there be cavitation? Is this an engine issue?

New Yamaha wear ring

New solas 14/20 dynafly (it is TIGHT; within spec for clearance on wear ring)

New solas intake grate

Filled the pump shoe with flex seal

Resealed ride plate, intake, etc

New fuel pump

New fuel injectors

New spark plugs

now the issue. When I pin this thing, it will almost immediately hit the rev limiter. From stop it will go for 1 second without it , but if I go WOT it will hit that rev limiter pretty much no matter how fast I’m going. Trim makes little difference. It seems like anything above 75 throttle it hits that limiter. I can do 45mph on it, and with the 75 throttle it gets good traction from what I can tell. I’m at a loss here! Where else can there be cavitation? Is this an engine issue?