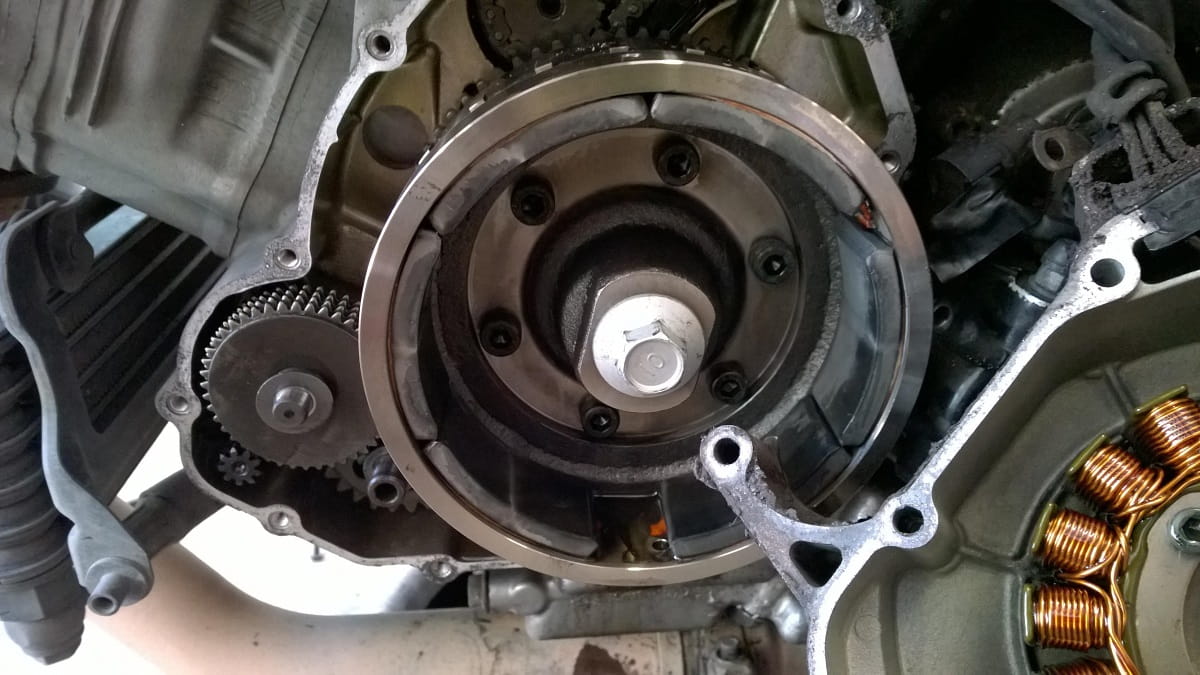

Too bad that a Flywheel needs to be installed and the Engine completely assembled, started and revved to test the Flywheel Magnet and Coil Voltage Output to find a sketchy Flywheel.

So if the AC Voltage Output is low, still don't know if the Coil or the Flywheel Magnets are bad or both.

Then, the Coil needs to be tested Cold for Resistance and Hot for Layer Shorts.

If the Coil is good, then it's the Flywheel. Now got to pull the bad Flywheel, find another (used) Flywheel, install it, and then test again...Pete and Repete till you get a good Flywheel. Not fun.

Will the Screwdriver test detect a split or divided magnetic Field in the same Magnet? I see that a cracked Magnet will act as two new Magnets with each having a Field Strength a fraction of the Original Magnet in proportion to it's new size. So, if a Magnet is cracked in two even halves, then each magnet will have 50% of the Original Magnet's Strength.

It will still produce a Current, but it will be weaker and probably erratic. Runs good at low rpms, but breaks up at high rpms.

I suppose that, with experience, one could get a "feel" for the normal OEM Magnet Strength acting on a Screwdriver. Guess seeing how much Steel Weight a good Flywheel Magnet can and should hold is the simplest way. That or buy a Gauss Meter ($75+) and measure the Field on a known good Flywheel, then one would have a baseline to use as a reference to check Flywheels.

Is there a way to figure/calculate what the Gauss Magnet rating should be based on the OEM specified max Output Wattage? Or the AC Voltage spec'd max Output? 'Cause different Flywheels have different strength Magnets, especially among different OEMs. Seadoo Magnetos typically have the highest Wattage Output due to all the Electrical Gizmos and Bells & Whistles built into the Seadoo Energy Hog Electrical System.

Any 'Lectricians, Kilowatts, 'Tronic Techs or Double E's know?

Just looking for different ways to skin the cat...'cause I'm curious