I bought a new set of carbs this spring and have only had them on for a few months and noticed some corrosion on the screws holding the retainer for the needle and seat in place and the screw for the diaphragm on the kidney. I have only ran vp110 and maxima k2 through these carbs. Wondering what would cause corrosion like this with only 2 months of ride time on these carbs.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Corrosion on carb screws

- Thread starter 800750

- Start date

Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

Have had that happen several times. If moisture gets in there it seams to sit right there!

lnteresting,oil causing corrosion?Might have something to do with your oil choice?

Don't certain oils have rust preventative (or water repelling?) properties specific to watercraft applications? Is K2 one of those oils?lnteresting,oil causing corrosion?

l never thought about moisture in oil? Maybe in the gas,but l would not think Vp 110Don't certain oils have rust preventative (or water repelling?) properties specific to watercraft applications? Is K2 one of those oilskin

Oils that leave the most protective coating have a lot of petroleum and butene in them. Most spec oil is formulated this way because it smokes the least and is cheap. Expensive racing oil is usually mostly ester which has higher temperature rating. Im not sure that a little premix would do much to make gasoline much less corrosive.

smokeysevin

one man with a couch

- Location

- Houston

That's nothing. Checkout this fuel pump from a "freshwater ski" I pulled out yesterday...

Sean

Sean

I can see one type of oil being less effective for corrosion protection than another, but it seems crazy to think that a particular type of oil could CAUSE corrosion.

Seems like if there was any water in there, it would be at the bottom of the little diaphram chamber, so I'm not seeing why it would be right in the middle where that screw is.

I can only conclude that it's not possible for that screw to be corroded. But clearly it is, sooo.......aliens.

Seems like if there was any water in there, it would be at the bottom of the little diaphram chamber, so I'm not seeing why it would be right in the middle where that screw is.

I can only conclude that it's not possible for that screw to be corroded. But clearly it is, sooo.......aliens.

There is one type oil that can cause corrosion, its glycol and used mainly for methanol. Klotz KL100 and KL200, do not use this stuff in a watercraft!! I use it in methanol/nitro fuel but the engine must be flushed with petroleum at the end of the day. Castor oil is better for corrosion but not nearly as good as petroleum.

There are reasons that stainless may not be the way to go for that application.Might try installing Stainless Steel Hardware for $8: https://www.ebay.com/itm/254540465180?hash=item3b43cb441c:g:Y6MAAOSwJJRfTFRP

View attachment 417091

A potential problem is dissimilar metal corrosion. Stainless steel and aluminum don't go together. Many aircraft have been scrapped for this reason. For watercaft, its a simple matter of money more than anything else. Stainless hardware is more expensive so it will never be used unless deemed necessary.

hornedogg79

dodgin' bass boats

Maxima K2 isn't TC-W3 rated. Designed for high temp moto racing. Our motors run much cooler and in water. Save your money for gas.

High ester content from an oil like redline is great for lubrication but very hygroscopic. Will absorb a lot of moisture from ambient.l never thought about moisture in oil? Maybe in the gas,but l would not think Vp 110

This thread has really become interesting with some of the answers given in reply to the question of moisture.High ester content from an oil like redline is great for lubrication but very hygroscopic. Will absorb a lot of moisture from ambient.

- Location

- Ahwahnee, CA

There are reasons that stainless may not be the way to go for that application.

If the screws do end up getting stuck or stripped, drilling the tops off to get them out would be tough with stainless. That’s one thought I had.

To be clear I really Dig maxima products - They spare zero expense when it comes to additive packages with their oils from supplier. I use their watercraft oil in my RN / her SXR / the ole beer cruiser VXR Pro.This thread has really become interesting with some of the answers given in reply to the question of moisture.

Flash-FX

No Square..No Round..FX-1

- Location

- South Jersey Shore

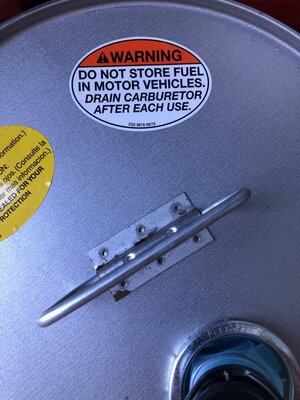

I run 20% VP113 and saw this sticker on the 5gal pail. My first thought was is this fuel really that corrosive to metals? Then again are the VP folks referring to regular carburetors with float bowls? like the good ole Holley 4bbl? In any event, if it's drained, it can't corrode. I haven't had any issues with corrosion yet.

Attachments

It is likely due to it being any oxygenated fuel and how they accomplish that. If you look closer at VP now, certain states cant get various fuels (U4.4, VP113, MR12 ect ect) due to the chemicals used for the oxygenation. If you're just chasing octane for your ski, pick a non oxy fuel if you dont want to worry about it at all. At 20% splash bend you prolly wont have an issue. Stuff like U4.4 left in a motocross carb will cause issues. Not to mention oxy fuels go stale quick when left to vent to atmospheric pressure.I run 20% VP113 and saw this sticker on the 5gal pail. My first thought was is this fuel really that corrosive to metals? Then again are the VP folks referring to regular carburetors with float bowls? like the good ole Holley 4bbl? In any event, if it's drained, it can't corrode. I haven't had any issues with corrosion yet.

If you ran something like U4.4 straight, not cut with pump gas, you'd have to increase the main size due to oxy content. But once that fuel sits in sun light or in a plastic container for a day, or left exposed to ambient, it will degrade and you will now have a rich condition. They're finicky. I purchase fuel in 55 gal drums and keep an N2 blanket on them, with a pipe and ball valve as a dispenser so they are never exposed to atmospheric pressure and the light ends dont leave the fuel when cracking the drum every time. Whatever is left in the tank at the end of day at the track goes into a 5 gal VP metal can like most people buy race fuel in. This is my MX race bikes, my ski's are stock so they just get pump.