- Location

- Asheville, NC

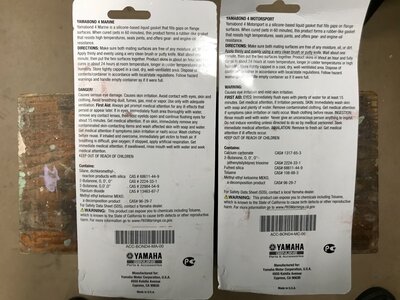

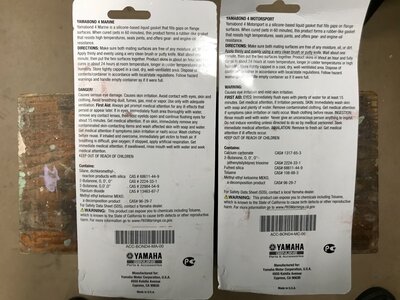

I’ve always used Hondabond in the past, but because I’m building a Yamaha engine I decided to grab a tube of Yamabond. I’m sure it’s probably about the same stuff and it’s not expensive. I did notice though that Yamaha has a few different Yamabond 4 mixtures. I grabbed the Motorsport and Marine versions. The packaging is almost the same, but lists some different ingredients. I can’t find much information about the difference for uses of these compounds. I would assume use the Motorsport for the engine and Marine for pump assembly? Just wondering what you all have to say