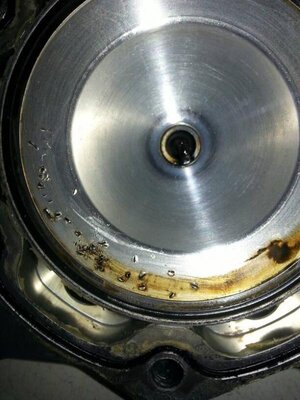

Hey guys I just pulled off my ada head, with less than ten hours on it, and found this. It's in the rear cylinder and on the exhaust side. Any idea what the problem could be? The pick marks are identical and are rectangular. I'm really hoping something in the crank didn't go. Is this still usable? There isn't any scoring on the cylinder wall thank god. Anything helpful I appreciate

Sent from my SCH-I535 using Tapatalk 2

Sent from my SCH-I535 using Tapatalk 2