- Location

- Lake Anna, VA

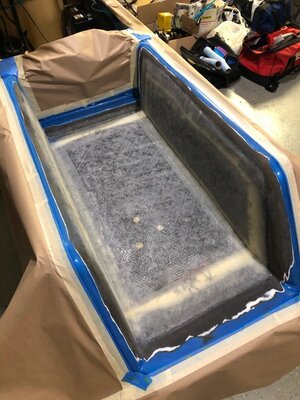

After it had time to cool and harden, I noticed there was a little flex above the pump shoe area where the foam hadn't properly spread into the thin void there. This is definitely an area I want strength and no gaps, so time to fill it in. Lets bust out the 1/2" bit and make a hole to pour a bit of foam in. Actually from experience, a bigger hole might be better, so lets go with the step bit and really widen it out. Then as I start to drill, I see much more tray material coming out than expected. Oh crap! You dumbass, there's a pump cavity 1/4" below that surface! Came very close to destroying an almost new 18V drill at that moment.

OK, I think that’s enough for that night. Tired, pissed off, and sick of this tray. Decided to end it on a higher note and used that bit to drill out the through hull for my electric bilge. The blue billet fitting looked good on there, but I still went to bed pissed AF!

So that was mid-June, almost 3 months into this fun. Most of my free time had gone into this thing, which hadn't been all that much until all my progress in the last couple weeks. The ski couldn't be done before my friends visited soon, and I had trips and other stuff going on after that. Plus the ski was now 20 min away in a hanger at the municipal airport, because a friend there is a glass expert and has lots of supplies and expertise to help finish this up better. All that meant it was definitely gonna take longer to finish up, and my summer was gonna be a little drier. Guess I'll have to take the kids out on the couches a little more. Little did I know just how long that dry spell was going to be....

Guess I'll have to take the kids out on the couches a little more. Little did I know just how long that dry spell was going to be....

(Time to finish getting ready for my camping trip. Might be a week before any more updates.)

OK, I think that’s enough for that night. Tired, pissed off, and sick of this tray. Decided to end it on a higher note and used that bit to drill out the through hull for my electric bilge. The blue billet fitting looked good on there, but I still went to bed pissed AF!

So that was mid-June, almost 3 months into this fun. Most of my free time had gone into this thing, which hadn't been all that much until all my progress in the last couple weeks. The ski couldn't be done before my friends visited soon, and I had trips and other stuff going on after that. Plus the ski was now 20 min away in a hanger at the municipal airport, because a friend there is a glass expert and has lots of supplies and expertise to help finish this up better. All that meant it was definitely gonna take longer to finish up, and my summer was gonna be a little drier.

(Time to finish getting ready for my camping trip. Might be a week before any more updates.)

Last edited:

Go get another jug of 50:1 and knock that out. One splash was enough, and she roared to life!

Go get another jug of 50:1 and knock that out. One splash was enough, and she roared to life!