- Location

- RI

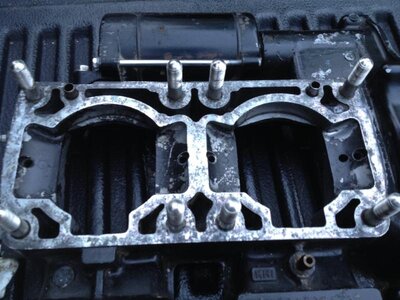

First build, first post on any forum so let me know if I am in the wrong place here. I was given a 1988 650sx and have been slowly disassembling and cleaning it for the past few months. It had been sitting with dirt, mold, and water in it for years so I was wondering if I should reuse the corroded lower case.

I am at the point where I am ready to start rebuilding it but I will probably take it slow since this is a first for me.

This is from a thread I posted on another site earlier:

____

I got it for free. It was sitting for many many years with water and dirt in it (none in the motor) and had a seized pump. Somehow the stock impeller had bound itself to the pump. It also had scored cylinders. Once I got the exhaust, battery, engine, etc. out I couldn't see any of the hull. It was caked in dirt, mildew, oil and grime. I never thought it would clean up but with some highly concentrated ZEP degreaser it miraculously shined right up. The ski also came with a bunch of extra parts, some installed, some not, and most of them pretty rough condition-wise:

Coffman pipe

Westcoast exhaust manifold

PRO racing ride plate

A lot of rough looking carbs (five or six) including duals with a r&d dual intake

Jetinetics ignition

Pole spring

Bad bones waterbox

500gph bildge - not hooked up

Plastic trigger throttle

Rear exit exhaust

No choke - primer set up

Two extra engine bay covers

One extra stock handle pole setup

Extra junk engine - sat outside for years with the head and flywheel cover off

Spare head

Other small things including spare electronics

I also bought/had done:

one step up wiseco top end kit

bore and hone service to match the pistons I bought

a skat trak straight 16 impeller

a new/used jet pump assembly

new oil seals

crankcase block off plate

oil pump block off plate (oil pump shaft was already broken as far as I could tell)

Used driveshaft bearing and plate that is slightly better than the one I had

CD based manuals

I have a few more things to purchase and some work on the hull but basically I may be able to start putting this thing back together soon. I am worried about corrosion on the bottom of the crank case and two of the ride plate screws aren't threading. Any tips on that?

I still need to purchase:

wrist pin bearings

liquid gasket

torque wrench

electrical parts

spark plugs

battery

Also the two engine mounting plates I have are pretty rusted. I grinded one down a bit and will probably just paint it and use it unless I find a nice one for a good price.

I also broke the stator mount in the disassembly process but I was able to salvage one from my junk motor and switch everything over.

I had trouble removing the drive coupler (and had to reassemble the engine to do it) so I bought a used one of those to replace the one I mangled.

Here are some pictures of the ski:

http://imgur.com/a/WcZO2

This album has a picture of the crank case that I am worried about:

http://imgur.com/a/sGomD

Here is the corroded crankcase again, what do you guys think?:

Thanks!

I am at the point where I am ready to start rebuilding it but I will probably take it slow since this is a first for me.

This is from a thread I posted on another site earlier:

____

I got it for free. It was sitting for many many years with water and dirt in it (none in the motor) and had a seized pump. Somehow the stock impeller had bound itself to the pump. It also had scored cylinders. Once I got the exhaust, battery, engine, etc. out I couldn't see any of the hull. It was caked in dirt, mildew, oil and grime. I never thought it would clean up but with some highly concentrated ZEP degreaser it miraculously shined right up. The ski also came with a bunch of extra parts, some installed, some not, and most of them pretty rough condition-wise:

Coffman pipe

Westcoast exhaust manifold

PRO racing ride plate

A lot of rough looking carbs (five or six) including duals with a r&d dual intake

Jetinetics ignition

Pole spring

Bad bones waterbox

500gph bildge - not hooked up

Plastic trigger throttle

Rear exit exhaust

No choke - primer set up

Two extra engine bay covers

One extra stock handle pole setup

Extra junk engine - sat outside for years with the head and flywheel cover off

Spare head

Other small things including spare electronics

I also bought/had done:

one step up wiseco top end kit

bore and hone service to match the pistons I bought

a skat trak straight 16 impeller

a new/used jet pump assembly

new oil seals

crankcase block off plate

oil pump block off plate (oil pump shaft was already broken as far as I could tell)

Used driveshaft bearing and plate that is slightly better than the one I had

CD based manuals

I have a few more things to purchase and some work on the hull but basically I may be able to start putting this thing back together soon. I am worried about corrosion on the bottom of the crank case and two of the ride plate screws aren't threading. Any tips on that?

I still need to purchase:

wrist pin bearings

liquid gasket

torque wrench

electrical parts

spark plugs

battery

Also the two engine mounting plates I have are pretty rusted. I grinded one down a bit and will probably just paint it and use it unless I find a nice one for a good price.

I also broke the stator mount in the disassembly process but I was able to salvage one from my junk motor and switch everything over.

I had trouble removing the drive coupler (and had to reassemble the engine to do it) so I bought a used one of those to replace the one I mangled.

Here are some pictures of the ski:

http://imgur.com/a/WcZO2

This album has a picture of the crank case that I am worried about:

http://imgur.com/a/sGomD

Here is the corroded crankcase again, what do you guys think?:

Thanks!

Last edited: