- Location

- Idaho

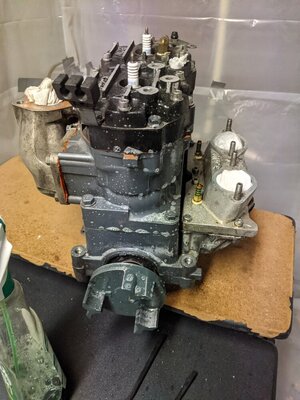

I've restored a number of jetskis, but I wanted this one to be special.

I wanted to do everything possible and do it properly. Cut zero corners.

My other goal was to make it make it after market as possible while making it look OEM.

Lots of pictures, and lots of detail, so sit back and enjoy!!

Also, let me know if you have any questions, would love to help!

Next project and forum post will be a Yamasaki X2 conversion full restore + 144 pump.

Ill start off with the final product picture, and then go into the project in detail.

I wanted to do everything possible and do it properly. Cut zero corners.

My other goal was to make it make it after market as possible while making it look OEM.

Lots of pictures, and lots of detail, so sit back and enjoy!!

Also, let me know if you have any questions, would love to help!

Next project and forum post will be a Yamasaki X2 conversion full restore + 144 pump.

Ill start off with the final product picture, and then go into the project in detail.