If you want to do it with a kawi 140 pump you will need to do glasswork to make it fit. My goal was to make the 144 pump fit with absolutely no modifications to the hull making it 100% returnable back to stock, all the modifying was done to the pump, fx1 pump shoe, and nozzle.

Setting the 2 pumps next to each other you can see the size difference (as if you haven’t seen that before looking at 144 swaps)

PUMP MODIFICATIONS

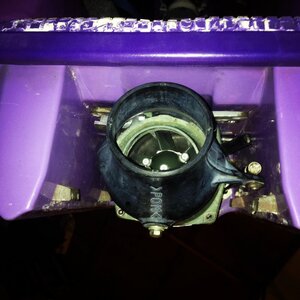

First thing you need to do is modify the pump mounting to make it bolt into the ski. I did this by pulling off the wear ring and machineing off the stock tabs and welding on 2 new tabs at the new required height (seriously spend some time to get the measurements dialed in before you start and note how my mod 144 and stock pump have the front and back tabs at different heights unlike a sj). The nozzle tabs just need to be extended so I used this as fixed part of the pump and make the wear ring tabs (forget the distance I measured off of the stock pump) lower. You will need to grind the stator some to make it fit the proper depth into the hull but don’t forget to pull the locating pins out of the stator and rotate it 180 degrees so the water pickup is on the correct side. (if your really good you can grind the mounting tabs off of the pump nozzle and clock that 180 degrees so the siphon port is on the right side then make your own tabs or you can just extend the siphen line and wrap it around the pump. You can use shorter bolts to attach the wear ring to the stator and another set to attach the stator to the nozzle. Then swap the fx1 pump shaft into the 144 pump.

TRIM

I did a manual trim for now with stainless hardware so I could get out on the lake without having to do any glass work to the ski. It worked good with the brackets that I made out of aluminum and when I needed to change the angle on the water I could reach under and spin the wing nut to tighten and loosen it against a jamnut on the otherside. And when I decide to go lever pull trim I can remake the two brackets

PUMP SHOE MODIFICATIONS

The pump shoe is a project of its own. I bought a second pump shoe just in case I broke the stock one removing it. But if you take your time with a heat gun and get it hot before you pry it should come out clean. Fill all the openings in the side and bottom with epoxy or whatever you can grind and shape. Mark out the diameter of the wear ring with pump seal on the pump shoe and grind away as much as possible of the shoe without breaking through too much on the top. Some people leave the shoe like that but I laid up 2 thin layers of fiberglass to blend it better and keep from having sharp points where the epoxy cavities met the aluminum again. I then polished off the pump shoe face that mounts to the seal with a scotch bright pad on an pneumatic angle grinder and sealed the pump shoe back in.

INSTALING

Pull the motor. And look down the shaft and shim then fully tighten the pump to the hull with the 4 main bolts and keep adjusting until the shaft floats dead center making sure to tighten completely before checking. Reinstall midshaft housing and motor with pump fully in. The steering linkage was to short on the fx1 to fit to the raider nozzle so I made an extension and also was able to set the distance inward to change the steering quickness. Finally there is the ride plate. I just opted for a tom21 ride plate to clear the pump but you could possibly get creative with stock style plate and make it work. (fyi JD ride plate will not work)

I believe that is the majority of the pump swap. Every ski will have its own challenges but I felt like it went pretty smoothly doing it this way. Let me know what you all think and if you have any questions.

Setting the 2 pumps next to each other you can see the size difference (as if you haven’t seen that before looking at 144 swaps)

PUMP MODIFICATIONS

First thing you need to do is modify the pump mounting to make it bolt into the ski. I did this by pulling off the wear ring and machineing off the stock tabs and welding on 2 new tabs at the new required height (seriously spend some time to get the measurements dialed in before you start and note how my mod 144 and stock pump have the front and back tabs at different heights unlike a sj). The nozzle tabs just need to be extended so I used this as fixed part of the pump and make the wear ring tabs (forget the distance I measured off of the stock pump) lower. You will need to grind the stator some to make it fit the proper depth into the hull but don’t forget to pull the locating pins out of the stator and rotate it 180 degrees so the water pickup is on the correct side. (if your really good you can grind the mounting tabs off of the pump nozzle and clock that 180 degrees so the siphon port is on the right side then make your own tabs or you can just extend the siphen line and wrap it around the pump. You can use shorter bolts to attach the wear ring to the stator and another set to attach the stator to the nozzle. Then swap the fx1 pump shaft into the 144 pump.

TRIM

I did a manual trim for now with stainless hardware so I could get out on the lake without having to do any glass work to the ski. It worked good with the brackets that I made out of aluminum and when I needed to change the angle on the water I could reach under and spin the wing nut to tighten and loosen it against a jamnut on the otherside. And when I decide to go lever pull trim I can remake the two brackets

PUMP SHOE MODIFICATIONS

The pump shoe is a project of its own. I bought a second pump shoe just in case I broke the stock one removing it. But if you take your time with a heat gun and get it hot before you pry it should come out clean. Fill all the openings in the side and bottom with epoxy or whatever you can grind and shape. Mark out the diameter of the wear ring with pump seal on the pump shoe and grind away as much as possible of the shoe without breaking through too much on the top. Some people leave the shoe like that but I laid up 2 thin layers of fiberglass to blend it better and keep from having sharp points where the epoxy cavities met the aluminum again. I then polished off the pump shoe face that mounts to the seal with a scotch bright pad on an pneumatic angle grinder and sealed the pump shoe back in.

INSTALING

Pull the motor. And look down the shaft and shim then fully tighten the pump to the hull with the 4 main bolts and keep adjusting until the shaft floats dead center making sure to tighten completely before checking. Reinstall midshaft housing and motor with pump fully in. The steering linkage was to short on the fx1 to fit to the raider nozzle so I made an extension and also was able to set the distance inward to change the steering quickness. Finally there is the ride plate. I just opted for a tom21 ride plate to clear the pump but you could possibly get creative with stock style plate and make it work. (fyi JD ride plate will not work)

I believe that is the majority of the pump swap. Every ski will have its own challenges but I felt like it went pretty smoothly doing it this way. Let me know what you all think and if you have any questions.