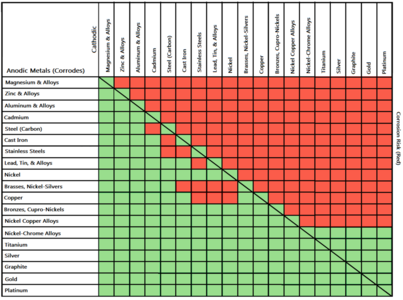

FYI, in case not already aware: stainless steel will gall against itself, so anytime you put stainless to stainless, you run the risk of a mechanical lock that you realistically can't recover from without drilling/machining. It's possible in some case, but do NOT count on it. So, the point is that if you mate stainless to stainless, you want to put a thin and complete layer of some type of barrier/lube in place. Loctite works pretty decent there, believe it or not. If it's not something that you want loctited, a high pressure bearing grease works great, according to people who do this type of stuff for a living. ( edit: a metal-appropriate anti-seize is really the right answer, but having to have a specific tube of anti-seize for the metals at hand was more of a hassle [ even figuring out the right one to use ] and I don't think enough water will get in there to wash the grease out before I take it apart again).

Regarding galvanic corrosion: not being in salt water is a huge help. I think a lot of the trash stuff that's available out there came from salt water skis. If you ride fresh water, and keep the ski out of the water most of the time, and remove the hood to vent moisture when not riding... I would be surprised to see extensive galvanic corrosion (no one I personally know has experienced it, but I'm sure someone will chime in saying they have). Rust, on the other hand, just needs some water and oxygen. I used some non-stainless (zync plated) washers at one point, and because of being installed/removed more than one, the plating was imperfect, and it rusted. Not enough to cause any big problems, but it did. The same exact setup but with stainless washers did not rust, as expected.

TL;DR: I'm a fan of stainless. Just use anti-seize type lube or loctite on all threaded surfaces that will mate stainless-to-stainless.