E350

Site Supporter

- Location

- Sacramento Delta

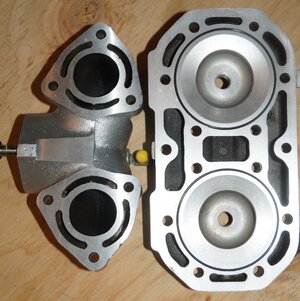

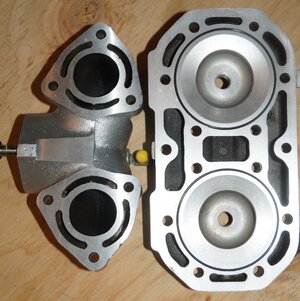

The 650 in the X2 was getting exhaust gasses in the water and wouldn't hold any kind of pressure when I blocked off the exhaust manifold and intake manifold. So I had the head resurfaced and bought new O-rings and have a couple of questions before I assemble it. $60 to have both re-surfaced. The head had a 0.015 inch twist but is now flat.

Two questions:

1. The O-rings in the photo are new and are good to 250 degrees Farenheit. They are not Viton. They are 90 durometer. I purchased them at Fluid Tech which is a local industrial (I mean massive 16" dia. 12' long actuators with 8' throws) hydraulics shop. Anyway this is the best they had. Are they the right material, softness and heat range?

McMaster-Car has a whole bunch of 042 O-rings of varying softness including Viton and silicone which are good to 400 or 450F.

Should I order two of these instead?

https://www.mcmaster.com/o-ring-seals

If so, which do you recommend?

2. Should I put some Threeond 1211 or Yamabond 4 or some other sealer on the aluminum around the water jackets?

I have the oem Kawasaki Jet Ski X-2 Waterccraft Service Manual, but the stock head uses a gasket not o-rings, so it is not helpful on this topic.

I asked over at pwctoday, but have not received a response.

Two questions:

1. The O-rings in the photo are new and are good to 250 degrees Farenheit. They are not Viton. They are 90 durometer. I purchased them at Fluid Tech which is a local industrial (I mean massive 16" dia. 12' long actuators with 8' throws) hydraulics shop. Anyway this is the best they had. Are they the right material, softness and heat range?

McMaster-Car has a whole bunch of 042 O-rings of varying softness including Viton and silicone which are good to 400 or 450F.

Should I order two of these instead?

https://www.mcmaster.com/o-ring-seals

If so, which do you recommend?

2. Should I put some Threeond 1211 or Yamabond 4 or some other sealer on the aluminum around the water jackets?

I have the oem Kawasaki Jet Ski X-2 Waterccraft Service Manual, but the stock head uses a gasket not o-rings, so it is not helpful on this topic.

I asked over at pwctoday, but have not received a response.

Last edited: